AIR Autonomous Navigation and Handling Robot System

The Kerui Technology AIR robot is an indoor autonomous navigation and handling robot designed for smart factories. It can easily achieve functions such as map editing, path adjustment, and station configuration without updating the on-site layout or adding additional facilities. Combined with Kerui Technology's rich system integration experience and powerful industrial information systems, it can provide customers with systematic solutions.

Performance characteristics

·Navigation control and scheduling system software with independent intellectual property rights, significantly reducing costs

·Multiple security protections (radar, ultrasonic, mechanical)

·Auxiliary secondary high-precision positioning ± 5 mm, meeting the requirements of handling and docking

·Laser SLAM natural navigation, no need to update site layout, no need for additional auxiliary facilities

·Independent suspension drive, adaptable to complex ground environments

·Multiple software options available, configurable for autonomous charging of robots

·Modular design, customizable and upgradable according to customer needs

·Adopting a fusion positioning scheme of inertial navigation, LiDAR, and odometer

Component Description

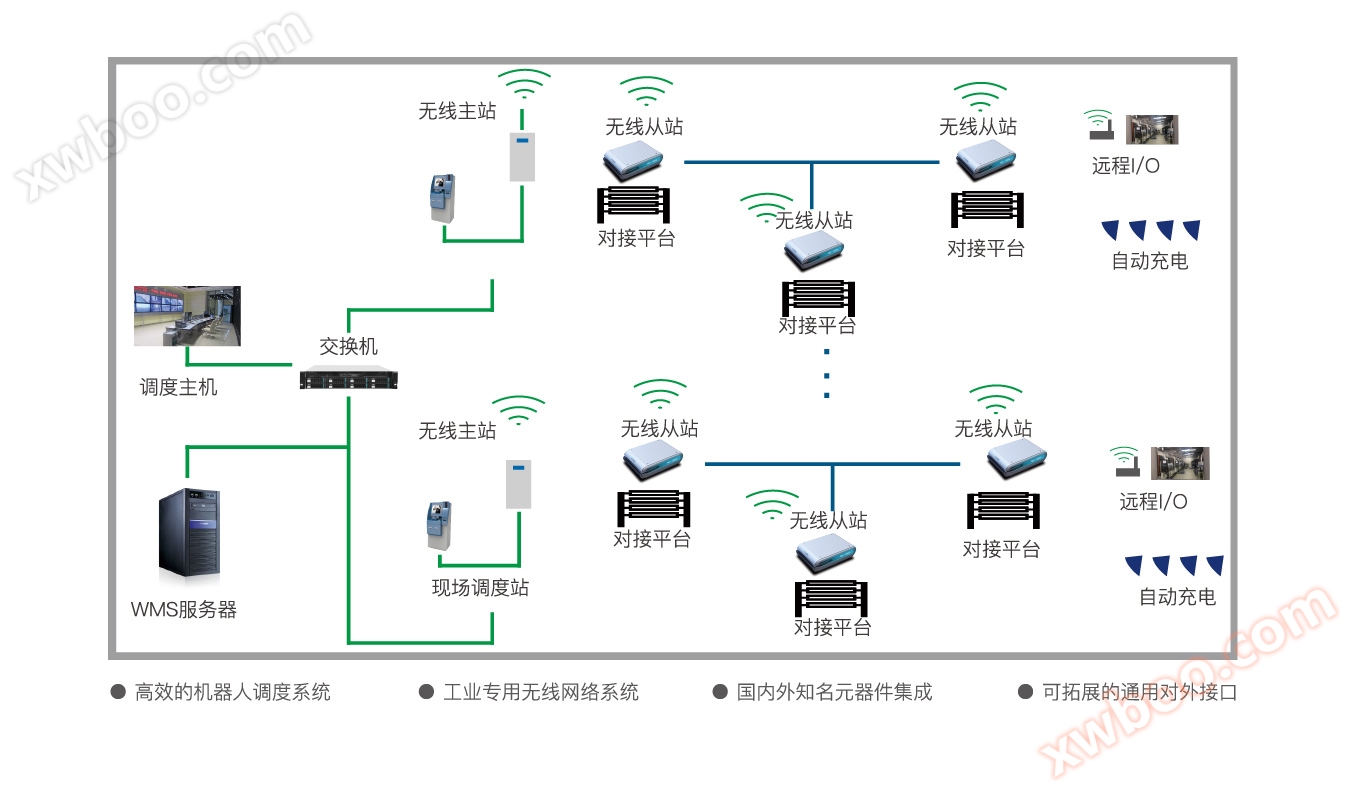

Dispatch Management System FCS

Task scheduling management: Based on specific job task requirements, allocate vehicles to execute set tasks

Vehicle status monitoring: Real time dynamic monitoring of the vehicle's operating position and current working status

Human computer interaction collaboration: can manually call the station for material requests, and the system automatically dispatches vehicles

Traffic control coordination: traffic control, dynamic switching, fleet increase and decrease scheduling, optimal path selection, task query, exception handling

Automatic charging management: monitoring vehicle battery level, optimal planning of vehicle charging tasks, manual automatic charging management

Communication Network Management: Vehicle Communication Management, Redundant Design of Communication Base Stations

Software integration management: a unified communication interface based on WebService, which can easily access various enterprise management platforms

|

Manual/automatic charging system Intelligent automatic charging: Low battery, the robot autonomously returns to the charging station for charging Real time battery display: Real time display of robot battery level |

|

Factory flexible handling robot system

Factory Material Information Management System

AIR Robot Application Case

01 Transportation of Photovoltaic Silicon Chips

Industry: New energy industry Application: Material turnover and handling between processing techniques for photovoltaic silicon chips

02 Express package handling

Industry: Logistics Industry Application: Various flexible handling of express delivery turnover centers

03 Cold chain fresh food transportation

Industry: Cold Chain Logistics Industry Application: Cold Chain Fresh Industry Poor Ground Environment Turnover and Handling

Specification parameters

|

AIR150 specification parameters | |||

|

Product Model/Name |

AIR150-LAC | control mode |

Auto/Manual |

|

Dimensions (L * W * H/mm) |

1250*650*280 | Driving direction | Forward, backward, turn |

|

Self loading (kg) |

<105 | Communication method | WiFi |

|

Load (kg) |

150 | Battery capacity (Ah) | 30 |

|

Working hours (hr.) |

8 (continuous full load) 0 | Charging time (h) | 3 |

|

Rotation radius (mm) |

0 | Type | DC48V lithium battery |

|

Turning radius (mm) |

488 | Charging method | Automatic/Manual (optional) |

|

Navigation method |

Laser SLAM | Braking method | Multi level deceleration parking/emergency stop |

|

Positioning accuracy (mm) |

±50/±3° | Auxiliary power supply | 24VDC (5VDC optional) |

|

Secondary positioning accuracy (mm) |

±5/±1° | Optional functional accessories |

Remote control box |

|

Drive mode |

Two wheel differential | Automatic charging station/manual charging station | |

|

Climbing angle (°) |

5/(1:11.5) |

Magnetic stripe high-precision positioning system/reflector+visual | |

|

Rotation angular velocity (°/s) |

120 | Docking transfer device (roller/belt docking station) | |

|

Maximum driving speed (Max. m/s) |

1.4 | Monitor mobile devices | |

|

Normal driving speed (Norm. m/s) |

0.8-1.0 | Remote control handle | |

|

Working environment temperature (℃) |

5-40 | Safety collision avoidance device |

Front mounted SICK laser radar, multiple pairs of ultrasonic waves at the front and rear, and multi-level comprehensive collision avoidance with a front mechanical bumper; Emergency stop button; Car light/speaker warning |

|

Relative humidity of working environment (RH%) |

5-90 | ||

|

IP degree |

IP20 | ||

|

Gap and step height (mm) |

10 | ||

|

Ground flatness requirements |

Floor FF25 (ACI117 standard): Hard concrete or oil felt horizontal surface (free of water/oil/dust) | ||

|

dispatching system |

On site work dispatch station: hundreds of AIR dispatch capabilities Main core functions: vehicle monitoring/map editing/task management/traffic control/logs and statistics/integration with factory ERP/WMS/MES |

||

|

User interface/interaction method |

Remote control box/MES, WMS and other information system docking/monitoring and warning on mobile devices (mobile phones and tablets) | ||

|

Product features and advantages |

Easy to deploy, secure, efficient collaboration, scalable, flexible, high reliability stability with powerful 8x7 working capability, rich customized load device user interface and auxiliary power supply: 1.8DI/8DO, 4AI/4AO, RS232 x2 user interface (optional) 2. External 24VDC user power supply (Optional 5VDC) |

||

|

Note: There are also AIR60/AIR300/AIR500, with loads of 60kg/300kg/500kg respectively | |||