|

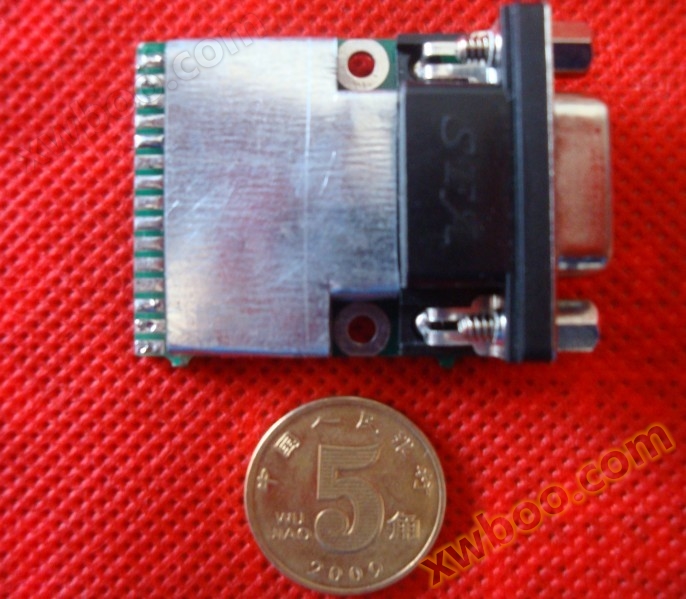

The high-precision strain data acquisition instrument has a measurement accuracy of 0.001%, a miniaturized 6-channel effective area equivalent to two coins, digital quantity and standard bus output, and all functions of intelligent settings are completed by software, such as channel selection, function settings, parameter calibration, etc. Personalized compensation can be embedded with strain sensors to make it an integrated digital sensor. Can be applied to high-end testing scenarios such as aerospace wind tunnels. Instrument Features

1. The high-precision data acquisition instrument achieves a measurement accuracy of 0.001% ± 35 nVP-PIt is particularly suitable for measuring static balances.

2. The chopper technology inside the instrument can stably measure the zero point with high precision; 50Hz notch technology can reduce 50Hz and its harmonics to below -120dB; Oversampling technology effectively reduces sampling noise; Digital filtering technology can filter out high-frequency interference signals outside the frequency band. Ensuring high precision and stability in measurement.

3. The high-precision data acquisition instrument consists of two parts: the host and the power supply. The small-sized host can be embedded inside the balance to directly output digital signals.

4. The high-precision data acquisition instrument can choose from 6 differential input channels connected to 6 independent strain full bridges, or 12 pseudo differential input channels connected to 12 independent strain half bridges; Program control completes functions such as automatic balancing, automatic compensation of reference voltage, debugging, calibration, etc. All information is permanently stored and not lost in case of power failure.

5. The host and computer communicate through RS485 bus, and one computer can manage multiple hosts simultaneously.

6. There are no mechanical movable parts inside the instrument (such as switches, potentiometers, etc.), and the input end is connected to the strain gauge with solder, which will not affect the reliability and long-term stability of the instrument due to factors such as oxidation and vibration.

Software diagram of high-precision acquisition instrument

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||