The equipment is suitable for high-speed laser etching and stripping of conductive materials on PET films and Glass substratesSeparation, etching, marking, slicing, material removal, and construction.

Applicable materials

Glass/film surface indium tin oxide (ITO), FTO, silver paste (Ag), carbon nanotubes (CNT), graphene, nano silver, molybdenum aluminum molybdenum, copper, polymer conductive film, aluminum film PERC、 Perovskite cells TCO、 Ultra fine line wide laser etching of coating materials such as carbon powder, zirconia, titanium oxide, zinc oxide, gold, etc. It can directly etch and mark white glass with laser, with a minimum line width of less than 10 microns.

Application industry

1.Touchscreen GF for mobile phones, cars, tablets, smart wearables, ordering machines, etc, GFF,OGS。

2.Etching of conductive film layer on OGS of car touch screen body.

3.Thin film solar cells, perovskite cells and other photovoltaic industries.

4.Emerging energy industries, such as electrochromic glass.

5.Luminous glass, outdoor display glass, display flexible film, etc.

6.White glass laser etching of wire slots, marking, drilling (guiding)

7.Other display screens.

Product Features

1.Laser etching is a dry etching process with a simple manufacturing process. All processing is automatically controlled by software, resulting in high product consistency and a yield rate of up to 99%. It is consumable free, environmentally friendly, reliable, and stable.

2.CCDThe camera automatically locates and has high processing accuracy.

3.The equipment is easy to operate, the drawing file is updated conveniently, the process is shortened, and the utilization rate is high.

4.The device control software can achieve automatic image segmentation, mobile splicing processing, and splicing accuracy up to ± 3 μ m

5.Low power consumption, fewer operators, no pollution, and low production costs.

Technical Parameter

laser device |

fiber laser |

Green Laser |

ultraviolet LASER |

wavelength |

1064nm |

532nm |

355nm |

Laser power |

20W |

10W |

10W |

pulse width |

Nanoseconds, femtoseconds, and picoseconds are optional |

Nanoseconds and picoseconds are optional |

Nanoseconds and picoseconds are optional |

Minimum focused spot |

<10 μ m (depending on the material, laser type, and pulse width) |

||

Minimum etching line width |

<10 μ m (depending on the material, laser type, and pulse width) |

||

Etching speed |

<4000mm/s |

||

Processing scope |

600*1200mm/600*600mm(Standard size, can be customized according to customer requirements) |

||

Maximum single format |

110mmX110mm (Standard configuration, optional according to requirements) |

||

CCDAutomatic positioning accuracy |

±3μm |

||

Positioning accuracy of linear motor worktable |

±2μm |

||

Repetitive accuracy of linear motor worktable |

±1um |

||

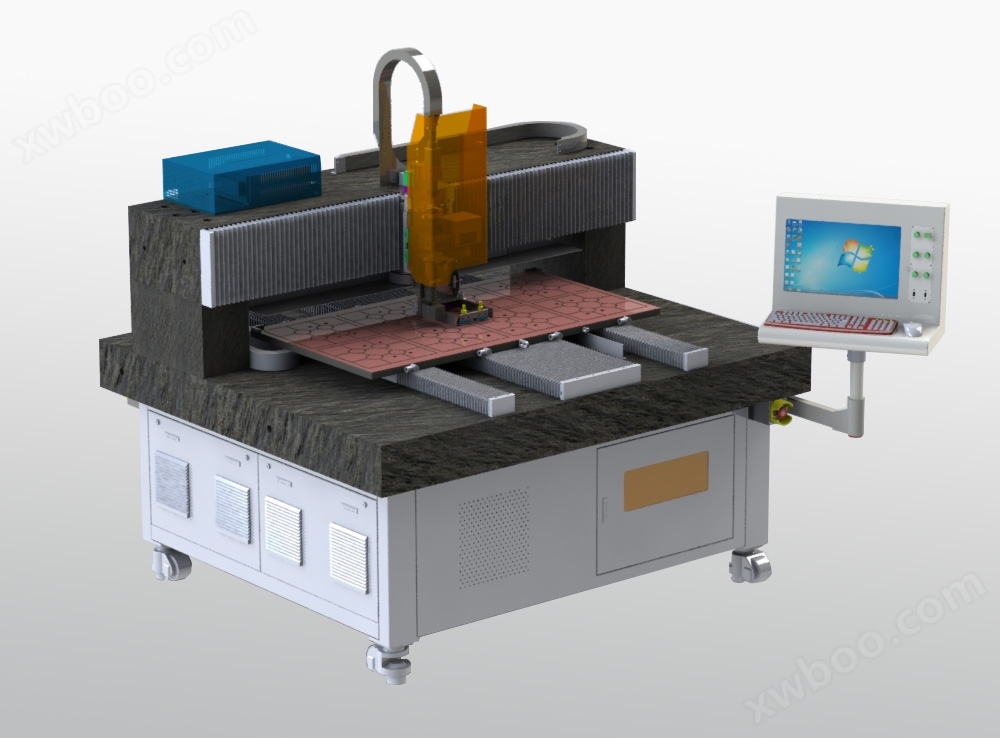

Equipment size |

1650mmL×1300mmW×1670mmH |

||

Equipment weight |

1800kg |

||

Capable of handling file formats |

Standard Gerber files, DXF files, PLT files, etc |

||

Yuanlu Optoelectronics has developed small-scale FTO and ITO laser etching equipment, which can be used for processing in the early experimental stage. Please feel free to inquire by phone.