- PRODUCT MODEL: FCL97-38.4-Y15KW

- rated power: 15000W

- reduction ratio: 1:38.4

- Fixed method: Flange type

- Motor level: 4P

1. Output speed:0.1-345rpm

2. Output torque: maximum18000N.m

3. Motor power: 0.18-132KW

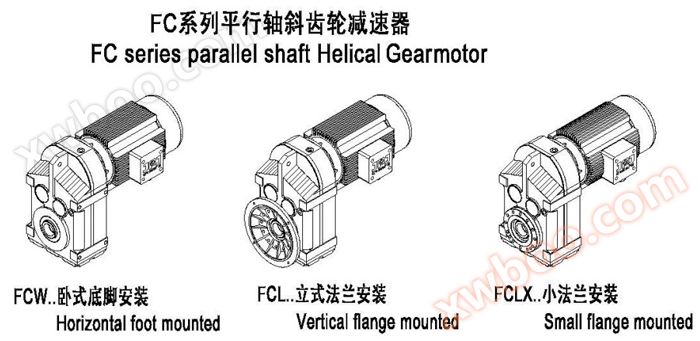

4. Installation form: Foot installation, flange installation, shaft installation, installation with expansion disc or torsion arm

5. Common models: FCW. Horizontal foot installation, FCL. Vertical flange installation, FCLX. Vertical small flange installation

6. Made in accordance with advanced technology requirements, the high-quality material steel iron box body is selected. The gear surface is carburized and quenched, and precision machined to form an electromechanical integration, forming a parallel helical gear transmission assembly. The reducer is equipped with various motors for use. The reducer motor has a compact structure, high overload capacity, smooth operation, strong universality, and an efficiency of up to 95%.

High quality materials, advanced design

The gears of the F series parallel axis helical gear reducer are made of 20CrMnTi material, which has been modulated and quenched to achieve a tooth surface hardness of 55 to 60HRC. The housing is made of gray iron 200; Adopting advanced modular design and high universality of accessories, it can effectively reduce spare parts inventory.

Precision machining, high efficiency, low temperature rise

The F series parallel axis helical gear reduction motor is precision machined by a machining center to ensure the accuracy of shaft parallelism and concentricity. High quality bearings are used to increase transmission efficiency, reduce temperature rise, and achieve good noise reduction effect.

Small size, saving installation space/strong>

The F-series parallel axis helical gear reduction motor consists of two pairs of helical gears or three pairs of helical gears, with parallel input and output, which can effectively save space and can be used in limited horizontal installation situations, such as on crane walking mechanisms.

Strong load-bearing capacity and high transmission efficiency

Parallel input and output, high overload capacity, can be equipped with a motor power of over 90KW, which is more efficient than the S series helical gear worm gear reduction motor. With the same speed ratio and power, it can save about 30% energy.