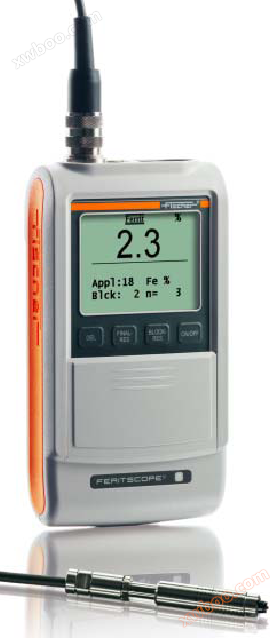

Detailed information of FERITSCOPE fmp30 magnetic induction ferrite content detector:

Instrument IntroductionChemical equipment and petroleum processing plants typically have to withstand high temperatures, pressures, and corrosion resistance. The external environment requires the steel used to have sufficient corrosion and acid resistance even at high temperatures. If the ferrite content is too low, the weld seam is prone to cracking when heated; If the ferrite content is too high, the weld will lose its toughness and ductility. For duplex steel, if the ferrite content is too low, the weld seam is prone to rupture when subjected to tension or vibration. FERITSCOPE fmp30 measures the ferrite content in austenitic steel and duplex steel using magnetic induction method. The instrument can identify all magnetic components, which means that in addition to delta ferrite, it can also identify its transformed form martensite. The instrument complies with the Basler standard and DIN 32514-1 standard, and is suitable for on-site testing. It can measure the ferrite content in austenitic coatings, stainless steel pipes, containers, and boiler welds, as well as other products made of austenitic steel or duplex steel. This is a standard compatible compact instrument used for non-destructive measurement of ferrite content in austenitic welded products and duplex steels. By using magnetic induction method, it is convenient and fast to measure ferrite content of 0.1-80% or ferrite number of 0.1-110FN.

Measurement of Ferrite Content with FERITSCOPE FMP30

|

1. Non destructive measurement of ferrite content in austenitic steel and duplex steel,

|

Main application areas

The chemical and petrochemical industries are increasingly using duplex steel, for example, the boiler vessels in Figures 1 and 2 are made of high-performance duplex stainless steel with high corrosion resistance. If the ferrite content at the weld seam is too low, it is prone to rupture when subjected to tension or vibration. However, when welding duplex steel, the ferrite content at the weld seam is easily exceeded due to improper welding additives or heat treatment. Only on-site testing can ensure that the processing does not alter the optimal ferrite content, preventing a decrease in mechanical or corrosion resistance performance.

|

|

Introduction to Measurement Principles

FERITSCOPE FMP30 is measured using magnetic induction method. The magnetic field area generated by the coil interacts with the magnetic components inside the workpiece, and the change in the magnetic field area generates an induced voltage in the second coil, which is proportional to the ferrite content, and then the voltage is evaluated. All magnetic components, including their transformed form of martensite in addition to delta ferrite, can be identified. The use of magnetic induction method to measure ferrite content has a special advantage. Sigma phase, also known as Fe Cr deposition, is accurately identified as non ferrite due to its high ferrite content and improper cooling conditions. On the other hand, it is very difficult to distinguish the sigma phase from the ferrite structure during metallographic sectioning experiments, which can lead to inaccurate assessment of ferrite content.

Calibration/standard film

In order to obtain comparable results, the instrument must be calibrated using internationally accepted secondary standard plates that can be traced back.

IIW (International Institute of Welding) has developed the method of manufacturing secondary standard plates according to DIN EN ISO8249 and ANSI/AWS A4.2 standards.

3. Helmut Fischer provides certified calibration standard plates for customers to calibrate instruments, which can be traced back to TWI secondary standard plates.

4. Two units are indicated on the standard plate: the number of ferrites FN and the percentage content% Fe.

5. The influence of workpiece geometry (curvature, thickness, etc.) on measurement can be reduced by setting correction factors before shipment or calibrating instruments with customized standard pieces.

6. Different calibration information is stored in different applications.

|

|

Calibration kit and optional probe ordering information

▪ Calibration standard kit CAL-SS% Fe-WRC 0.3/10 includes standard plates: approximately 0.4, 2.5, and 10.5% Fe (0.4, 2, and 9 FN) 602-279

▪ Calibration standard kit CAL-SS% Fe-WRC 1.5/30 includes standard plates: approximately 2.5, 10.5, and 30% Fe (2, 9, and 33 FN) 602-239

▪ Calibration standard kit CAL-SS% Fe WRC 10/80 includes standard plates: approximately 10.5, 30, and 80% Fe (9, 33, and 110 FN) 602-277

▪ The main calibration standard kit CAL-SS% Fe-WRC 0.3/80 includes: approximately 0.5, 2.5, 14.5, 30, and 63 %Fe (0.5, 2, 9,33 and 90 FN) 602-776

FERITSCOPE fmp30 Magnetic Induction Ferrite Content Detector