1、 Introduction:

The float type decanter has a simple structure and is mainly composed of a float, a decanting pipe, a hose, a connector, and a bracket. The working principle is based on gravity, buoyancy, and flow pressure, so the performance is very stable, without the need for operation and maintenance, and without power consumption; However, a typical float type decanter, like a rotary decanter or a sleeve type decanter, requires the assistance of spring elasticity, mechanical force, electricity, control components, and sealing friction. Its complex structure not only requires energy consumption and regular maintenance, but also poses various problems such as misoperation, mechanical failure, and control component failure.

2、 Characteristics:

1. The main body of the equipment adopts a U-shaped rotating support, and all components are made of stainless steel, which is compact and runs smoothly.

2. The float adopts a floating design, which can maintain the depth of the water at the decanting layer constant according to the constantly changing water level in the pool, achieving the best effect of decanting.

3. The main body of the equipment operates without power, and during the overall operation of the equipment, except for the installation of an electric valve at the discharge outlet, all other components do not use any power.

4. When the equipment is running, the decanting speed is uniform, the water surface is stable without fluctuations, the main power is noiseless, and the decanting can continuously rise with the continuous increase of water level.

5. The underwater rotating part adopts a mechanical rotating device, which can ensure the long-term operation of the rotating part of the decanter without aging or breaking.

6. The device body is not made of any rubber parts and has a long service life.

7. During normal operation of the equipment, the electric valve can be used to make arbitrary adjustments to the decanting range between 0 and the maximum decanting depth.

8. The inlet of the water collection tank is equipped with an automatic mudguard, which can effectively isolate sludge during aeration in the tank.

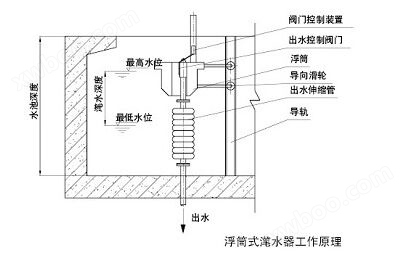

3、 Working principle: