VIP member

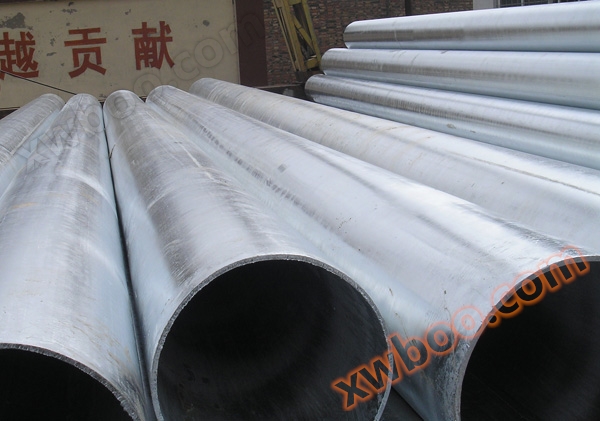

Hot dip galvanized spiral steel pipe

To improve the corrosion resistance of spiral steel pipes, general spiral steel pipes are galvanized

Product details

To improve the corrosion resistance of spiral steel pipes, general spiral steel pipes are galvanized. Galvanized spiral steel pipes are divided into two types: hot-dip galvanizing and cold galvanizing. Hot dip galvanizing has a thick galvanized layer, while cold galvanizing has a low cost and a surface that is not very smooth. Blown oxygen welded pipe: used as a pipe for oxygen blowing in steelmaking, generally using small-diameter welded steel pipes with eight specifications ranging from 3/8-2 inches. Made from steel strips of 08, 10, 15, 20, or 195-Q235, aluminum infiltration treatment is necessary to prevent corrosion.

Hot dip galvanized spiral steel pipe is produced by reacting molten metal with iron substrate to form an alloy layer, thereby combining the substrate and coating. Hot dip galvanizing is the process of first pickling steel pipes. In order to remove iron oxide from the surface of the steel pipes, after pickling, they are cleaned in an ammonium chloride or zinc chloride aqueous solution or a mixed ammonium chloride and zinc chloride aqueous solution tank, and then sent to a hot-dip galvanizing tank. Hot dip galvanizing has the advantages of uniform coating, strong adhesion, and long service life.

Hot dip galvanized spiral steel pipe: The steel pipe substrate undergoes complex physical and chemical reactions with the molten plating solution, forming a corrosion-resistant and tightly structured zinc iron alloy layer. The alloy layer is integrated with the pure zinc layer and the steel pipe substrate. Therefore, it has strong corrosion resistance.

Weight coefficient of hot-dip galvanized spiral steel pipe

Galvanized spiral steel pipe nominal wall thickness (mm): 2.0, 2.5, 2.8, 3.2, 3.5, 3.8, 4.0, 4.5.

Galvanized spiral steel pipe coefficient parameters (c): 1.064, 1.051, 1.045, 1.040, 1.036, 1.034, 1.032, 1.028.

Note: The mechanical properties of steel are important indicators to ensure its ultimate performance (mechanical properties), which depend on the chemical composition and heat treatment system of the steel. In steel pipe standards, tensile properties (tensile strength, yield strength or yield point, elongation) as well as hardness and toughness indicators are specified according to different usage requirements, as well as high and low temperature performance requirements from users.

Steel grade: Q215A; Q215B; Q235A; Q235B。

Test pressure value/Mpa: D10.2-168.3mm is 3Mpa; D177.8-323.9mm is 5Mpa

Current national standard

National standards and dimensional standards for galvanized spiral steel pipes

GB/T3091-2015 Welded steel pipes for low-pressure fluid transportation

GB/T13793-2008 Straight seam welded steel pipes

GB/T21835-2008 Welded steel pipes - Dimensions and weight per unit length

Mechanical properties of galvanized spiral steel pipe

① Tensile strength (σ b): The maximum force (Fb) that a specimen can withstand at break during the tensile process, divided by the original cross-sectional area (So) of the specimen to obtain the stress (σ), is called tensile strength (σ b), measured in N/mm2 (MPa). It represents the maximum ability of metal materials to resist damage under tension. In the formula: Fb - the maximum force borne by the specimen when it is pulled apart, N (newtons); So -- the original cross-sectional area of the sample, mm2。

② Yield point (σ s): The stress at which a metal material with a yield phenomenon can continue to elongate without increasing the force (maintaining a constant) during the tensile process, known as the yield point. If the force decreases, the upper and lower yield points should be distinguished. The unit of yield point is N/mm2 (MPa). Upper yield point (σ su): The maximum stress at which the specimen yields and the force decreases for the first time; Lower yield point (σ sl): The minimum stress in the yield stage when the initial instantaneous effect is not considered. In the formula: Fs - yield force during the tensile process of the specimen (constant), N (Newton) So - original cross-sectional area of the specimen, mm2。

③ Elongation after fracture: (σ) In a tensile test, the percentage of the increase in gauge length of the specimen after fracture compared to the original gauge length is called elongation. Expressed in σ, with units of%. In the formula: L1- the gauge length of the sample after being pulled apart, mm; L0- the original gauge length of the sample, mm。

④ Sectional shrinkage rate: (ψ) In a tensile test, the maximum reduction in cross-sectional area at the reduced diameter of the specimen after fracture, expressed as a percentage of the original cross-sectional area, is called the cross-sectional shrinkage rate. Represented by π, the unit is%. In the formula: S0- original cross-sectional area of the sample, mm2; S1- the minimum cross-sectional area at the point where the sample shrinks after being pulled apart, mm2。

⑤ Hardness index: The ability of a metal material to resist the indentation of a hard object on its surface, known as hardness. According to different testing methods and applicable ranges, hardness can be divided into Brinell hardness, Rockwell hardness, Vickers hardness, Shore hardness, microhardness, and high-temperature hardness. The commonly used hardness for pipes includes Brinell, Rockwell, and Vickers hardness.

Brinell hardness (HB): A steel ball or hard alloy ball of a certain diameter is pressed into the surface of the specimen with a specified test force (F), and after a specified holding time, the test force is removed to measure the indentation diameter (L) on the surface of the specimen. The Brinell hardness value is the quotient obtained by dividing the test force by the surface area of the indentation sphere. Expressed in HBS (steel ball), the unit is N/mm2 (MPa).

Online inquiry