Installation dimension diagram of low-speed impeller, price of QJB4/4-1800/2-56B impeller

Installation diagram of low-speed submersible thruster

scope of work

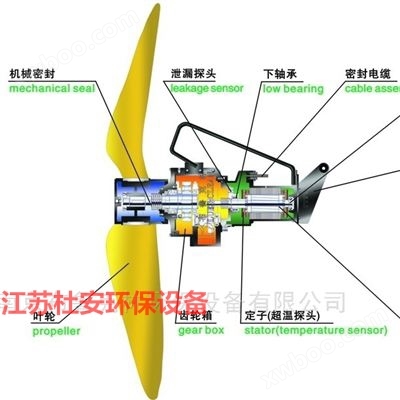

Structure of Jiangsu Du'an Environmental Protection Submersible Propeller

A. General requirements

The customer or owner shall adjust the installation position of the thruster reasonably based on the provided pool type and water depth, and provide drawings and performance curves.

Underwater thruster(The 2-plade type is low-speed.

When the underwater thruster is working, it is required that the horizontal flow velocity at the bottom of the pool be greater than0.3m/s to prevent sedimentation.

The underwater thruster should be able to move up and down along the guide rod, rise and fall freely, and can be adjusted horizontally and vertically, and equipped with a safety braking device.

B. The structure of underwater thrusters

A propeller

Underwater thrusters should use axial flow impellers with good self-cleaning function, no vibration during operation, and optimized design, and undergo dynamic balance tests. The impeller should be able to efficiently stir and push the flow of fluid at the bottom of the pool. All blades should have the same shape.

The propeller of the underwater thruster should be designed with hydraulic balance and unobstructed drag.

The propeller and shaft are fixed at the end of the shaft with a key connection and sealed. The impeller and shaft must be locked with a locking device to prevent them from loosening, whether they rotate forward or occasionally reverse.

Propellers should undergo dynamic and static balance tests.

The underwater thruster should be coaxial with the motor.

The shaft of the underwater thruster propeller must be an extension of the motor shaft.

B bearing

The minimum design life of all bearings is100000 hours.

C mechanical seal

The underwater thruster should be equipped with a dual mechanical seal system. Sealed operation within the oil chamber, which can lubricate overlapping sealing surfaces at a stable flow rate.

D motor

The motor of the underwater thruster should be a submersible motor, and the insulation level of the stator winding and stator inlet wire should beThe H-level insulation temperature is 155 ℃, and the protection level of the motor is IP68.

The motor should be designed to continuously handle agitationStart 10 times per hour in a medium at 40 ℃. To monitor the temperature on each phase winding, a thermal switch should be installed in the stator inlet coil, which can be connected to the motor overload protection and to the control cabinet.

The supplier shall provide the signal specifications of each protective sensor of the motor to ensure that the signal can be transmitted toMCC。

Install an over temperature sensor on the stator winding of the motor.

Install anti leakage sensors to prevent liquid from entering the stator winding.

The water detection device should be installed in the cable connection room of the motor.

The rated power of the motor should be greater than the specified point axis power1.1 times.

E Cable inlet sealing

The cable inlet sealing design should be able to eliminate a certain amount of torque and form a waterproof submersible seal. The seal should ensure the replacement of the cable and cannot be sealed with epoxy, silicon or other secondary sealing systems.

Measures should be taken to prevent air exchange inside and outside the cable due to temperature differences in the cable joint section.

The cable should be properly fixed in water, and the contractor should provide fixing devices.

F guide rod and bracket

The guide rod should be supported at three points: upper, middle, and lower. The bracket should be designed according to the installation position of the mixer and the actual structural diagram of the pool.

Main component materials of Jiangsu Du'an submersible thruster

|

Underwater thruster propeller |

Strengthening polyurethane |

|

axle |

AISI 420 |

|

mechanical seal |

Tungsten carbide or silicon carbide |

|

Chain/wire rope |

AISI 316 |

|

Guide rod and bracket |

AISI 316 |

|

Hangers and supports |

AISI 316 |

|

All connecting accessories/embedded anchor bolts |

AISI 316 |

Delivery inspection

Each underwater thruster should undergo the following tests (not limited to):

·Appearance inspection

·Operation status test

·Air pressure test inside the submersible motor cavity

·Measurement of various indicators of submersible motors

·The components of the underwater thruster that withstand working pressure undergo a 5-minute hydrostatic test without leakage, with a test pressure of 1.5 times the working pressure but not less than 0.2 MPa.

INSTALLATION REQUIREMENTS

According to the standardGB50231 "General Code for Construction and Acceptance of Mechanical Equipment Installation Engineering" is used for equipment installation and inspection.

Inspection and Testing

Conduct clean water and sewage operation tests according to the relevant requirements of the owner.

During operation, it should meet the following requirements:

·The motor current should not exceed the rated current.

·The underwater thruster runs smoothly without any abnormal sounds or vibrations.

·All sealed parts must not have any oil or water leakage.

·When the underwater thruster slides on the guide rail, there shall be no jamming phenomenon, and the guide rail and bracket shall not be deformed.

Jiangsu Du'an Environmental ProtectionQJBLow-speed thrusterSuitable for various water treatment processes and industrial processes that require uniform mixing and reaction of solid and liquid two-phase or solid, liquid, and gas three-phase media. Mainly composed of submersible motors, reducers, spiral impellers, seals, hand cranked hoisting mechanisms, installation systems, and electrical control devices, etc

QJBLow-speed thrusterModel Description

QJB1.5/4-1800/2-42/S/P

QJB - Low speed thruster (submersible thruster)

1.5- Motor power (KW)

4- Motor level

42-- Impeller diameter (mm)

2-- Number of leaves

1800- Rated speed (r/min)

S/P - Material: S represents stainless steel, P represents polyurethane