|

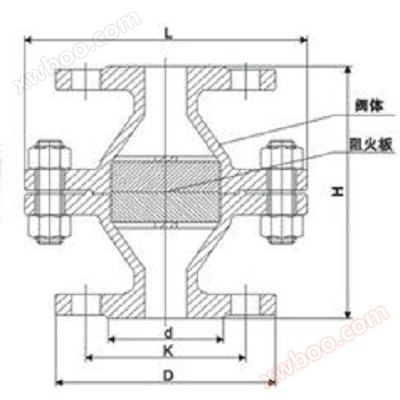

Product specifications |

DN200-800 |

|

pressure rating |

1.0-4.0MPa |

|

Operating Temperature |

-30—480℃ |

|

Shell material |

WCB 304 (CF8) |

|

Flame retardant core material |

304 316 |

|

gasket |

PTFE gasket, metal gasket, graphite gasket |

|

connection method |

flange connection |

|

Applicable Medium |

Various non corrosive or weakly corrosive gas media in oil products |

|

Explosion proof level: |

BS5501: 11A、11B、11C |

|

Product brand |

Shanghai Nanshi |

Large caliber flame arresters are used to prevent external flames from entering equipment or pipelines containing flammable and explosive gases, or to prevent flames from spreading between equipment and pipelines. It is used to prevent the spread of hydrogen flames outward

A safety device is composed of a solid material (flame retardant element) that can pass through gas and has many small channels or gaps. Pipeline explosion-proof flame arrester is used to prevent flammable gases and liquids

A safety device that prevents the spread of flames and prevents explosions caused by backfire. Usually installed on pipelines that transport or discharge flammable and explosive gases. Such as torches, heating and combustion systems, and petroleum gas recovery systems

Unified or other flammable gas systems.

Flame arresters are widely used in pipelines for heating fuel gas, natural gas, and liquefied petroleum gas, as well as in systems for oil and gas recovery, coal mine gas emissions, and gas analysis. They can effectively ensure the safety of gas pipelines and systems

Safe operation of body usage points. The function of a flame arrester is to prevent the spread of flames of flammable gases and flammable liquid vapors, and to prevent explosions caused by backfire. Fuel usually installed in front of the furnace

On the main gas pipeline, it is usually a short pipe with a diameter thicker than the fuel gas pipeline and flanges at both ends. About ten copper wire mesh are installed perpendicular to the airflow inside the pipe, usually cast with a certain thickness

The aluminum ring compresses the perimeter of the mesh and forms a certain gap. Due to the excellent heat dissipation performance of copper mesh, when the flame encounters the copper mesh, it will extinguish due to a sharp drop in temperature, thus playing a role in flame prevention. Its main

The function is to allow flammable and explosive gases to pass through, and to prevent suffocation of flames that enter the storage tank from the outside. The characteristic of using this pipeline flame arrester under low temperature conditions in high-altitude regions is that it can

To be used in conjunction with or separately from the ventilation tube. Suitable for storing Class A oil products with a flash point below 28 ℃ and Class B oil products with a flash point below 60 ℃, as well as for storing materials on dome shaped tanks capped with nitrogen gas,

The principles of gravel flame arresters and mesh flame arresters are the same as those used in pipelines.Flame arresters are designed and manufactured based on the principle that flames extinguish due to heat loss when passing through narrow pores of a thermal conductor. Explosion proof pipeline

The flame arrester is mainly composed of two parts: the shell and the filter element. The shell should have sufficient strength to withstand the impact pressure generated by the explosion. Corrugated filter element made of stainless steel, copper nickel alloy, aluminum or aluminum alloy

support The corrugated flame arrester can organize the violent flames of detonation and withstand the corresponding mechanical and thermal effects. It has low flow resistance and is easy to clean and replace.

Large caliber flame arrestermain purpose:

1. On pipelines transporting flammable gases.

2. Torch system.

3. Oil and gas recovery system.

4. The pipe network for heating furnace fuel gas.

5. Gas purification and chemical system.

6. Gas analysis system.

7. Coal mine gas emission system.

8. Flammable and explosive solvent systems (such as reaction vessels and tank vents)

Requirements for flame arrester testing: Whether the performance of the flame arrester can achieve the expected effect and play the role of flame arrester, it is necessary to test the flame arrester.

In addition to having a certain mechanical strength, flame arresters should also undergo explosion resistance and burn resistance tests, and meet the requirements of the test standards.

Explosion proof test refers to the process of igniting combustible gases within a certain distance from a testing device, and preventing and extinguishing flames or sparks that cannot pass through the flame arrester. This type of test is called explosion proof test.

The flame resistance test is a test in which a combustible gas flame passes through a flame retardant layer and continues to burn on top of the flame retardant layer without reignition. The fire-resistant layer can withstand a certain period of flame combustion without being burned out,

This type of test is called the burn resistance test.According to the purpose of use, flame arresters can have both explosion resistance and flame resistance, or they can only have explosion resistance or flame resistance. Therefore, the flame arrester

Explosion resistance and burn resistance are the main items for testing and identifying flame arresters. Flame arresters that have not undergone such testing and identification cannot be used.

Flame arrester standardFlange standards: GB, HG, SH, HGJ, JB, ANSL, JIS and other standards. (User specified, please indicate pressure level) Execution standard: GB13347-92《

Fire resistance performance and test methods of flame arresters for petroleum gas pipelines ", SH/T3413-99" Selection, inspection and acceptance of flame arresters for petroleum gas pipelines in petrochemical industry ", HG/T20570.19-95" Fire resistance

The settings of the device. Production, inspection and acceptance standards for flame arresters: SY/T0512-1996 "Flame arresters for petroleum storage tanks", testing basis: GB5908-86 "Performance and experimental methods for flame arresters for petroleum storage tanks".

Large caliber flame arresterMain performance:1. The explosion resistance performance is qualified, and it has been tested for 13 consecutive times to prevent fire. 2. The fire resistance performance is qualified, and there is no tempering phenomenon after 1 hour of fire resistance test. 3. The shell water pressure test is qualified. Reasonable structure, heavy weight

Lightweight and corrosion-resistant. Easy to maintain and install.

There are currently two main views on the working principle of flame arresters: one is based on heat transfer; One is based on the wall effect.

Principles for maintenance and repair of large caliber flame arresters:

1) The flow direction mark on the flame arrester must be consistent with the flow direction of the medium.

2) To ensure the performance of the flame arrester meets its intended use, it is necessary to carefully read the instructions provided by the manufacturer before installing the flame arrester, and carefully check whether the label is consistent with the requirements of the installed pipeline.

3) It should be checked every six months. Check whether the fire-resistant layer has defects such as blockage, deformation, or corrosion.

4) The blocked fire-resistant layer should be cleaned thoroughly to ensure that each hole is unobstructed, and any deformed or corroded fire-resistant layer should be replaced.

5) When cleaning the flame arrester core components, high-pressure steam, non corrosive solvents, or compressed air should be used for blowing, and sharp hardware brushes should not be used.

6) When reinstalling the fire-resistant layer, the gasket should be updated and the sealing surface should be confirmed to be clean and undamaged, without any air leakage.

Shanghai Nanshi is a professionalflame arrestermanufacturerThe products produced by the company include breathing valves, flame arresters, fire-resistant breathable caps, fire-resistant vacuum pressure caps, aluminum alloy ball valves, and aluminum alloy single flanges

Ball valve, oil discharge port, double door bottom valve, oil measuring hole and other seriesSupporting attachments.

Welcome to visit our website【http://www.shhxfcj.com/If you have any questions You can call us and we will do our best to provide you with high-quality service.

Telephone:.