Methane, non methane, benzene systemsVOCS online process gas chromatograph

instrumentintroduce

CMS-6000 modelThe online process gas chromatograph is a customized instrument developed for the online monitoring system of organic pollutants. It is designed for air detection at exhaust gas discharge outlets (pollution source types) in chemical parks, chemical workshops, pharmaceutical factories, and other locations. Due to the high water vapor content, high concentration, and complex working conditions of organic waste gas at the exhaust gas discharge outlet, a smoke filtration sampling system is specially configured to filter the smoke, dust, and water vapor in the exhaust gas. The entire gas pipeline adoptsHigh temperature heat tracing at 175 ℃ enables the sample to smoothly reach the chromatographic column for substance separation, and then detect methane/non methane total hydrocarbons through flame ionization detector (FID).

CMS-6000 modelThe online process gas chromatograph is capable of continuous operationWorking 24 hours a day, 24 hours a day without stopping, meeting the requirements for high-intensity online monitoring of ambient air in designated locations. IoT technology, with built-in IP protocol stack in the instrument, enables remote wireless/wired transmission of experimental data.

Instrument characteristics

1. The instrument has excellent stability and durability, and can work continuously 24 hours a day without stopping, meeting the requirements of high-intensity online testing.

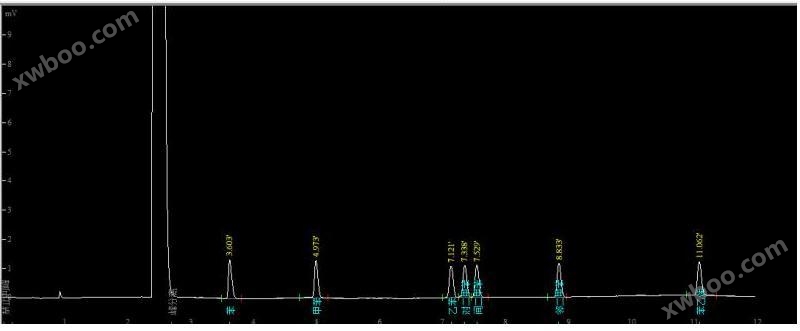

2. Instrument configuration 10Inch industrial tablet, which can view test peak graphs through its built-in chromatography software.

3. Configure a high-temperature heat tracing pretreatment device to reduce sample loss and improve the accuracy of detection results.

4. The methane and non methane total hydrocarbons in the mixed gas can be obtained in one go, with high testing efficiency.

5. Adopting a ten way valve and dual tube quantitative method to ensure the accuracy of test results, with a repeatability error of ≤ 2%.

6. The FID detector adopts a car ignition design, with a maximum of 10000 ignitions and is durable.

7. The body adopts modular technology to avoid interference between internal circuits and improve testing accuracy.

8. The core components are made of imported materials, effectively ensuring the overall airtightness and high reliability of the system.

9. The entire gas system adopts a fixed flow design, and ordinary operators can complete instrument debugging.

10. Equipped with automatic shutdown of hydrogen gas function to prevent hydrogen leakage and ensure the safety of the system.

Technical Parameter

| project | index |

| detectability | Methane, non methane total hydrocarbons, total hydrocarbons |

| range | Methane (0.1-1000) ppm; Non methane total hydrocarbons (0.05-100) ppm/(1-1000) ppm |

| detector | Hydrogen Flame Ionization Monitor (FID) |

| detection limit | 0.1ppm (methane), 0.05ppm (non methane total hydrocarbons) |

| repeatability | RSD≤3% |

| Analysis cycle | ≤4.0min |

| Power supply | AC220V 50Hz 800W |

| work environment | Temperature: (5-35) ℃, Humidity: (20%-90%)RH |

| Air source requirements | Carrier gas: high-purity nitrogen or zero grade air (>99.995%); Gas: high-purity hydrogen gas Auxiliary gas: zero grade air |

| output | 4-20mA RS232/RS485、 Ethernet |

| size | 19 inch standard chassis |

application area

CMS-6000 modelThe online process gas chromatograph (pollution source type) is a customized equipment developed for the online monitoring system of organic pollutants. It is suitable for building a complete online monitoring system and is installed at the exhaust outlet of chemical plants, pharmaceutical factories, and other waste gas treatment facilities to analyze the treated waste gas24-hour uninterrupted testing, real-time monitoring of exhaust gas treatment progress, to avoid severe air pollution.

Update time: September 4, 2020 16:48:45