μMLAIt is a new technology of desktop laser direct writing, which is a suitable entry-level tool in the field of microstructure research applications.μMLAIt has flexibility and customizability, and can support samples as small as millimeters in size.

μMLAPrinciple:

Using a variable intensity laser beam to perform variable dose exposure on the corrosion-resistant material on the substrate surface, and after development, the required pattern is formed on the surface of the corrosion-resistant layer.

μMLAIt has the following advantages:

Ÿhigh resolution

Ÿmaskless

ŸFlexibility and customizability

ŸVarious experimental conditions can be set

major function

Ÿ Grating scanning exposure

ŸQuick exposure of complex contentgraphic

Ÿgrayscale lithography

Technical capabilities

ŸSubstrate size: from5Millimeters to5inch

ŸFeature size: as low as0.6 µm

ŸWrite speed(4 µmResolution:200 mm 2 / min

ŸReal time autofocus system

ŸFacing it directlyaccurate

ŸEasy to use operating software

Ÿ 2Available optical settings

ŸExposure module selection: Grating and/Or vector scanning

Ÿvariable resolution

ŸPainting mode

ŸWavelength (grating scanning):390 nmperhaps365 nmExposure wavelength

ŸWavelength (vector scanning):405 nmand/perhaps375 nm

Wide angleCamera, used for alignment and inspection

application

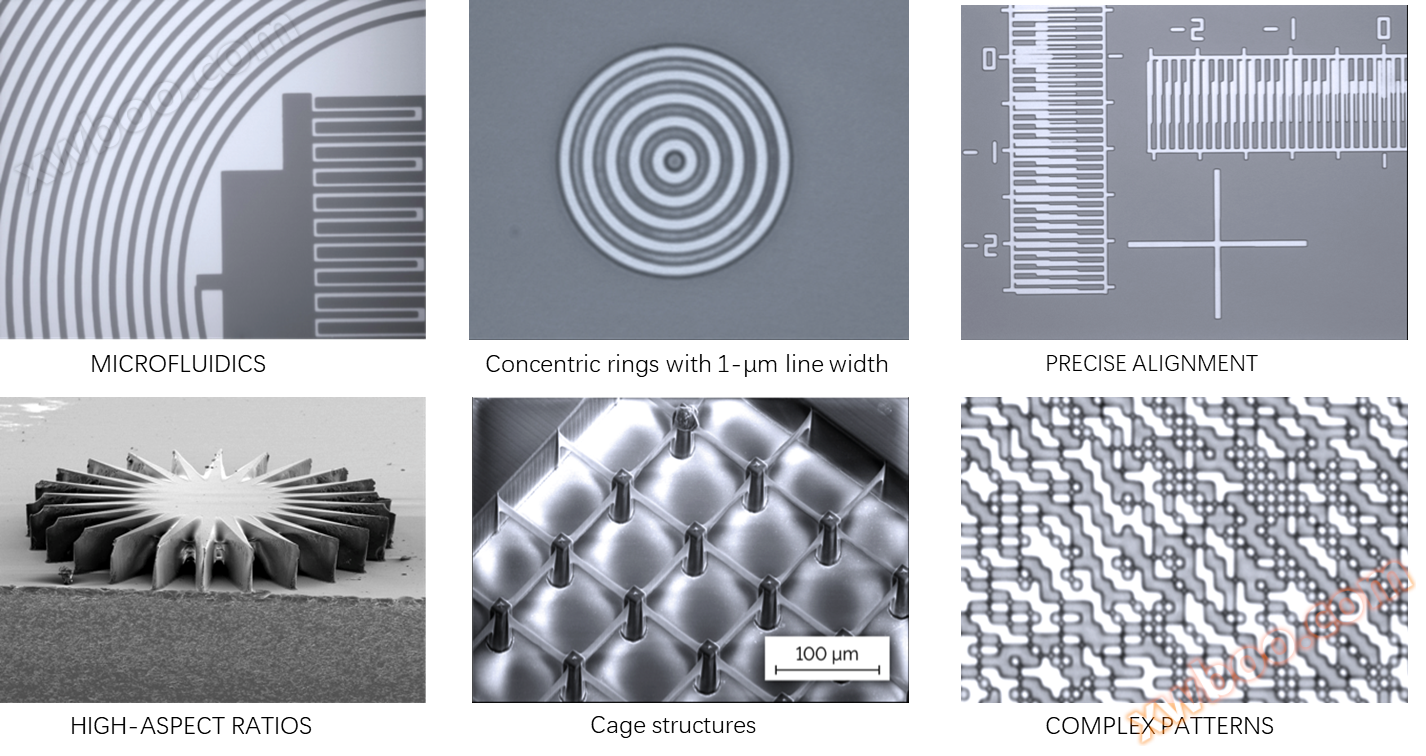

Semiconductor chips, microelectromechanical systems, microfluidics, micro optics, mask templates, and other fields with micro nano structure requirements.