preface:

Bromate is internationally recognized as a potential carcinogen at level 2B. It is a byproduct generated by natural water sources such as mineral water or mountain spring water (containing bromides) after ozone disinfection. Internationally, the allowable concentration of bromate in drinking water is within 0.01mg/L as stipulated by the World Health Organization and the US Environmental Protection Agency. Due to the high stability of bromate once generated, it is difficult to remove it using conventional methods. The removal of bromate is an industry challenge. Due to the fact that bromate is a byproduct of ozone sterilization and ozone is widely recognized as an effective disinfection method, it is difficult to determine what technology can replace ozone sterilization.

Under normal circumstances, the content of bromate in natural mineral water is almost zero, but due to its high mineral ion content, bromide ions (Br -) are commonly present. When using ozone to sterilize mineral water containing bromide, bromide easily reacts with ozone and is oxidized into bromate, which exists in the form of Br03- in the water,In many cases, the decomposition of bromate produces nitrite, which often needs to be considered in the bromate removal process. To address this issue, Peide Water Treatment has developed and produced equipment for removing nitrite from mountain spring water and mineral water.

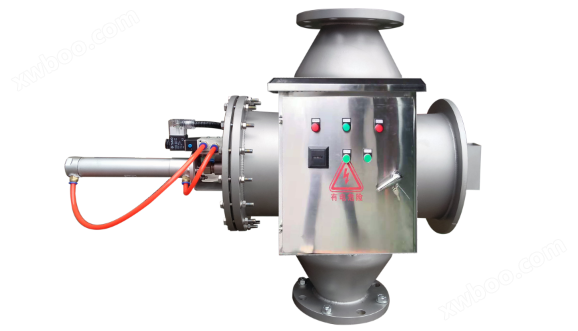

Mountain spring water mineral water bromate removal equipmentProduct Introduction:

Our company has developed and produced a bromate removal equipment for mountain spring water mineral water based on independent patents. After on-site use by multiple mineral water plants and testing by national authoritative testing institutions, there is no generation of bromate or nitrite, and the treatment is not affected by pH value. There is no need to add carbon dioxide gas to reduce the pH value of mineral water, nor does it change the taste and quality of mineral water, nor does it require activated carbon. Simply install before the mineral water filling process, it is easy to integrate into existing natural mineral water production lines, with easy installation and good replaceability. The reaction chamber of the bromate removal equipment for mountain spring water mineral water is made of food grade 304 or 316L stainless steel, with a mirror polished design on the inside and outside. The processing flow can be customized according to user requirements, with a small footprint, low equipment investment, and low processing costs. The processing of traffic can be customized according to user requirements.

With the strict implementation of the national standard "Drinking Natural Mineral Water" (GB8537-2008) on October 1, 2009, how to reduce the content of bromate in natural mineral water has become a very concerned issue.

The conventional processes for drinking natural mineral water include pumping, ozone sterilization, storage and transportation, secondary ozone addition, and most Post bottling and other steps. In addition to the presence of many organic and inorganic substances, there are also polybromides in the ppb level in natural raw water. At the initial addition of ozone, bromides react with ozone to form bromide (BrO3-), which can generally reach a concentration of 10-20 ppb. After the second addition of ozone, it is bottled and left in water. Adding ozone twice before bottling (with a concentration of approximately 100 ppb) is to ensure that there is a certain amount of ozone residue in the bottled water, which can disinfect both the water and the bottle cap simultaneously. This is crucial in the bottling process.

In response to this issue, the R&D department of Changzhou Peide Water Treatment has conducted extensive research on Chinese mineral water and developed a solution based on the operational experience of dozens of factories over the years. This process fully considers the specific needs of different stages of water treatment and the characteristics of two different ultraviolet technologies. A mountain spring water mineral water bromate removal equipment has been developed, which requires a replacement for ozone disinfection equipment because the equipment itself thoroughly disinfects and avoids the generation of bromate during ozone disinfection.According to the feedback from relevant mineral water and mountain spring water production enterprises, they can all meet the national standards: 10ppb, significant effect, thorough disinfection.

Why is there bromate in water

When bromate appears in drinking water, firstly there must be bromine in the water, and secondly there must be conditions for its production:One factor is that the source water itself is rich in bromides. Generally, pure water does not contain bromides, so there is no problem with bromate; In natural mineral water, only a very small number of regions in China contain bromides,Another factor is the use of higher concentrations of ozone for sterilization. The combination of two factors produces a higher concentration of bromate. At present, the production of bottled water in China mainly uses ozone disinfection, which has a good disinfection effect and can ensure that the bacterial indicators of bottled water meet relevant national standards; In addition, the use of ozone technology has low production costs and is easy to use. When both of the above conditions are met, bromate will appear in water.

The hazards of excessive bromate:

At present, there is no convincing direct evidence to prove the effects of long-term intake of bromate in mineral water on people's bodies. However, research on animals has shown that adding potassium bromate to the drinking water of experimental mice increases the risk of carcinogenesis, as well as non cancerous renal cell tumors, thyroid and peritoneal mesothelioma. The results of bacterial mutagenicity testing using bromate are very clear. In the experiments conducted so far, it has been fully demonstrated that it causes chromosome breakage in cells and DNA damage in vivo. Due to its experimental results in animal bodies, bromate is generally considered a potential carcinogen.

Performance advantages and characteristics of bromate removal equipment for mountain spring water and mineral water:

| Performance advantages | characteristic |

| No residue | 1. Independently invented patented products, photon processing technology |

| Green disinfection | 2. Treatment does not require lowering the pH value of water to acidify it |

| Eliminate bromate | 3. The treatment effect is not affected by the pH value of the raw water |

| 4. Do not change the taste and quality of mineral water | |

| 5.Not damaging beneficial mineral components such as silicic acid in mineral water | |

| 6.Easy installation and good replaceability | |

| 7.Small footprint, low equipment investment, and low processing cost |

Calculation of UV dose

The bactericidal effect is a function of UV dosage. This is the product of the intensity level of ultraviolet light and the exposure time. The design of the equipment for removing bromate from mountain spring water and mineral water in Peide Water Treatment aims to optimize energy and contact time to ensure the correct level of treatment is provided and maintained. The bromate removal equipment provided by Peide Water Treatment can kill a wide range of microorganisms including Escherichia coli, mold, yeast, Salmonella, Shigella, Staphylococcus aureus, influenza cryptosporidium, hepatitis, and Legionella.

Microbial indicators of mineral water mountain spring water:

project |

require |

Total colony count/(CFU/mL)≤ |

50 |

Coliform bacteria/(MPN/100mL)≤ |

3 |

Mold/(CFU/mL)≤ |

10 |

Yeast (CFU/mL)≤ |

10 |

Pathogenic bacteria (Salmonella, Shigella, Staphylococcus aureus) |

not detectable |

Comparison between the equipment for removing bromate from mountain spring water and mineral water of Peide Company and a certain photon:

| project | Pei De | A certain photon |

| workmanship | No need for ozone sterilizer | Used after ozone disinfection |

| nitrite | No nitrite is produced | Generate nitrite, unable to meet the requirements of bottled water |

| performance | Adopting more advanced electronic ballasts, reliable, stable, with complete protection measures, and long lamp life | Using inductive ballasts results in high power consumption. Low efficiency and short lifespan of the lamp tube |

| consume power | The power consumption is only 1/3 of that of a photon; mdash; 1/5; | High power consumption |

| External dimensions | Small external dimensions | Large external dimensions |

Application scope of the equipment for removing bromate from mountain spring water and mineral water:Disinfect mountain spring water and mineral water and prevent the formation of bromate

Process flow of bromate removal equipment for mountain spring water and mineral water:Mineral water, mountain spring water → storage tank → booster pump → sand filter → activated carbon → precision filter → ultraviolet sterilizer → ultrafiltration → sterile water tank → mountain spring water mineral water bromate removal equipment → filling

Equipment installation precautions:

Ultraviolet radiation has a powerful killing effect on bacteria and also causes certain harm to the human body. The most vulnerable part of the human body is the cornea of the eye, so it is not advisable to look directly at a lit lamp at any time to avoid eye injury. In case it is necessary to look, ordinary glass (wearing glasses) or transparent plastic sheets should be used as protective masks, as ultraviolet radiation can hardly penetrate ordinary glass or transparent plastic sheets. Do not misuse quartz glass. Once injured, there is no need to panic. Facial burns can cause skin loss in a few days and heal without treatment. Eye injuries can cause redness, swelling, tearing, and stinging, and take about three to four days to heal. Anyway, in case of injury, it is still recommended to seek medical treatment immediately at a doctor's office.

Pipeline connection of bromate removal equipment for mountain spring water and mineral water:

1. Determine the installation location (the equipment should be installed close to the filling machine to avoid affecting the use effect), and construct the pipeline according to the requirements of the "Standard Pipeline Connection" diagram;

2. Control valves must be installed at the inlet and outlet;

3. The working pressure rating of the connecting flange and control valve of the pipeline shall not be lower than the design pressure of the product (not less than 0.6MPa);

4. When connecting the pipeline to the bromate removal equipment for mountain spring water and mineral water, no stress deformation should occur that affects the installation and sealing of the quartz glass tube;

5. Before finally connecting the inlet and outlet flanges, remove the dust-proof tape from the inlet and outlet of the equipment to prevent impurities from entering the cavity;

After the pipeline connection is completed, conduct a water inspection to check for any leaks at the connection points and equipment body;

7. Connect the compressed air pipeline of the cylinder to the pneumatic solenoid valve interface, and the air pressure should not be lower than 0.4MPa.

Caution: Do not let iron filings, welding slag, and other debris fall into the equipment chamber when connecting pipelines.

Attention: When conducting water inspection, the pressure must reach the operating pressure and not exceed the design pressure.

Suggestion: To prevent impurities from damaging and contaminating the quartz casing in water, it is recommended to install a filter at the inlet end of the bromate removal equipment for mountain spring water mineral water.

Suggestion: To ensure that untreated water does not flow into the water area in the event of a sudden power outage, it is recommended to install an electromagnetic control valve at the outlet of the equipment.

8. The equipment is fastened to the foundation with bolts through the screw holes of the supporting feet, and a 1-meter space is reserved at the terminal to install quartz sleeves and ultraviolet lamps.

Warning: Strict grounding is required to prevent electric shock accidents caused by leakage.

Attention: When lifting and transporting the reactor, please protect the stainless steel surface to avoid affecting its use and appearance.

Electric controller:

Attention: The distance between the electronic controller and the bromate removal equipment for mountain spring water and mineral water should not exceed 1.8 meters to avoid affecting normal use.

The equipment is grounded internally, and the customer's power supply must be grounded.

Attention: As the quartz sleeve has already been installed at the factory and the equipment has been subjected to water pressure testing, there is no need to remove the quartz sleeve again. You can directly install the lamp tube according to the following steps.

Power on test:

Before starting, it is necessary to check for any errors in the electrical connections.

Turn on the power switch and check if the lamp is emitting light normally.

Warning: It is strictly prohibited to open the sealing gland while it is powered on.

Warning: Ultraviolet radiation can cause serious damage to the eyes. It is strictly prohibited to look directly at exposed ultraviolet light with the naked eye. UV resistant glasses must be worn during inspection.

Attention: Do not frequently turn on or off the power supply to avoid affecting the lifespan of the lamp.

function:

When using the bromate removal equipment for mountain spring water mineral water for the first time, to remove air, please open the inlet valve and let the water slowly flow through the equipment for 2-3 minutes to fill the chamber with water before opening the valve.

At the beginning, the UV intensity of the lamp tube decays by about 10% within 100 hours of use, and then the UV intensity decays very slowly.

Precautions for equipment use:

1. It is strictly prohibited to start frequently, especially in a short period of time, to ensure the lifespan of the UV lamp.

2. Regular cleaning: According to the water quality, the ultraviolet lamp tube and quartz glass sleeve need to be cleaned regularly. Use alcohol cotton balls or gauze to wipe the lamp tube, remove dirt from the quartz glass sleeve, and wipe it clean to avoid affecting the transmission rate of ultraviolet rays and the sterilization effect.

3. When replacing the lamp tube, first unplug the lamp tube power socket, remove the lamp tube, and then carefully insert the cleaned new lamp tube into the mountain spring water mineral water bromate removal device, install the sealing ring, check for water leakage, and then plug in the power supply. Be careful not to touch the quartz glass of the new lamp tube with your fingers, otherwise it may affect the sterilization effect due to stains.

4. Preventing UV radiation: UV radiation has a strong killing effect on bacteria and can also cause certain harm to the human body. When starting the disinfection lamp, direct exposure to the human body should be avoided. If necessary, protective glasses can be used. Do not directly face the light source with your eyes to avoid burning the eye mask.

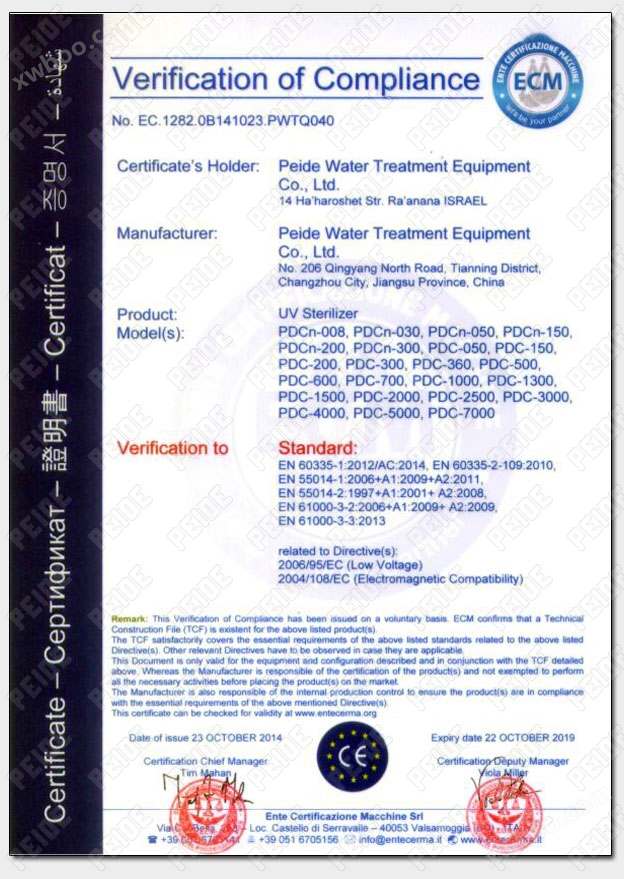

Received EU CE certification:

On site case of bromate removal equipment for mountain spring water and mineral water:

[Customer] Ningbo Simingshan Mineral Water Co., Ltd

【 Application 】 Removal of Bromate Salt in Mineral Water Production Process

【 Installation location 】 Ningbo

[Contract Number] 2027918A5

Inspection, production, debugging, and packaging of bromate removal equipment for mountain spring water and mineral water

Analysis and Inspection of Stainless Steel Material

After purchasing the raw materials for the bromate removal equipment of mountain spring water and mineral water, Peide Water Treatment Company's testing personnel will conduct strict testing on the raw materials.

Packaging diagram for shipment of bromate removal equipment for mountain spring water mineral water: