preface:

The most common and difficult to control problems in the production of bottled water and natural mineral water are microbial contamination, oxygen consumption, free chlorine, bromate, nitrite and other quality issues. Although a certain amount of bacteria is allowed in national standards, practice has proven that mineral water products that meet drinking hygiene standards but have a small amount of bacteria present during initial testing are difficult to store within their shelf life, and secondly, they cannot meet ideal national quality requirements in other physical and chemical indicators.

The microbial contamination of bottled water and mineral water mainly includes contamination by Escherichia coli, Staphylococcus aureus, mold, anaerobic bacteria, Streptococcus faecalis, Pseudomonas aeruginosa, Clostridium perfringens, and actinomycetes. Bacteria can convert nitrate in mineral water and purified water into nitrite, and the unstable manipulation of ozone can affect the indicators of bromate, thereby affecting human health. The mycelium of fungi and actinomycetes can form white filamentous floating and white flocculent substances, which still troubles many mineral water and bottled water companies.

Nitrite in water poses various hazards to humans and animals. Ion exchange, reverse osmosis, electrodialysis, biological and denitrification, chemical and chemical catalytic nitrification can all remove nitrite from water, each with its own advantages and disadvantages The ion exchange method concentrates nitrite in the medium or waste liquid, which can easily cause secondary pollution; Biological methods have the characteristics of high efficiency and low consumption, but require large investment; Although the chemical reduction method can reduce nitrite ions to harmless nitrogen gas, its reaction requires higher temperatures and has lower efficiency For the treatment of nitrite in underground deep water with low content and low processing capacity, chemical oxidation method has the advantages of simple equipment and low treatment cost. Not applicable to mountain spring water and mineral water.

For large and medium-sized mineral water and mountain spring water bucket filling enterprises, in the traditional production process, quality factors such as microorganisms, molds, algae, nitrite, etc. are controlled in the finished water, and a more stable and environmentally friendly sterilization method cannot be found to control the process. For the new national standard control of bromate, it is more difficult to control a key point (the use of ozone sterilization often leads to the source of excessive bromate due to the inability to control the appropriate proportion). In this case, Peide Water Treatment provides a more mature and environmentally friendly sterilization solution for high-efficiency sterilization products in the beverage process: Mountain Spring Water Mineral Water Nitrite Removal Equipment. At the same time, we also develop and produce equipment for removing bromate from mountain spring water and mineral water.

The hazards of nitrite in water:

If the human body accidentally ingests a large amount of nitrite, it can lead to methemoglobinemia, resulting in low blood oxygen, causing headaches, weakness, difficulty breathing, and even skin and mucous membranes turning purple blue. Infants are particularly susceptible to this condition.

2. Nitrite itself is not a carcinogen, but in environments such as stomach acid, nitrite reacts with secondary amines, tertiary amines, and amides in food to produce the strong carcinogen N-nitrosamine, which is a globally recognized carcinogen. The toxicological research on nitrite shows that a single intake of 0.2-0.5 grams of nitrite can cause acute poisoning, and 3 grams can lead to death.

3. Due to the reduced oxygen supply in body cells caused by nitrite, long-term intake of nitrite by the human body can lead to intellectual decline. Children who drink water with high nitrite content for a long time will have slower auditory and visual conditioned reflexes.

Requirements for the restriction of nitrite in drinking water according to different standards:

Standard number |

Standard Name |

Limit requirement (mg/l) |

Indicator Description |

Classify according to standard preparation |

GB5749-2006 |

Standards for drinking water quality |

1 |

Not labeled as N or NO2 |

Water quality reference indicators |

GB17324-1998 |

Hygienic standard of bottled purified water for drinking |

0.002 |

Calculated as NO2 |

Physical and chemical indicators |

GB8537-1995 |

Drinking natural mineral water |

0.0050 |

Calculated as NO2 |

Pollutant indicators |

GB8537-2008 |

Drinking natural mineral water |

0.1 |

Calculated as NO2 |

Pollutant indicators |

----- |

American Drinking Water Quality Standards |

1 |

Calculated by N |

pollutant |

Reasons for unqualified nitrite detection:

Nitrite is a strong oxidant. The pollution of nitrite in bottled water may come from two aspects:

One possibility is water source pollution from bottled water production enterprises, where a large amount of nitrate fertilizers are applied to the soil near the water source, resulting in high nitrate contentUnder the action of aquatic microorganisms, acid salts are converted into nitrite;

On the other hand, improper microbial control during the production process leads to high levels of microorganisms in the finished water, which convert nitrate into nitrite, resulting in excessive nitrite content.

Key points of the new standard for mountain spring water:

1. Reference standards: Codex Alimentarius Commission CAC "CODEXSTAN227-2001: General Standard for Bottled/Packaged Drinking Water (excluding Natural Mineral Water)" and World Health Organization WHO "Guidelines for Drinking Water Quality", etc;

2. Physical and chemical indicators: bromate≤ 0.01mg/L; Chlorite≤ 0.2mg/L;

3. Microbial indicators: total bacterial count≤ 50cfu/mL, pathogenic bacteria (Salmonella, Shigella, Staphylococcus aureus) should not be detected;

4. Water source requirements: The water source must be taken from within the mountain range and cannot be filled in other places. A protection zone must be established for the water source, and specific testing indicators must be set up. Those who do not meet the requirements shall not claim to be“ Drinking natural mountain spring water;

5. Label: The main cation (K+, Na+, Ca2+, Mg2+) content range of the product must be indicated.

The working principle of the nitrite removal equipment for mountain spring water and mineral water:

The contaminated water enters the equipment through the inlet and flows through the reactor of the nitrite removal equipment for mountain spring water and mineral water. Using proprietary technology, the deoxyribonucleic acid (DNA) and ribonucleic acid (RNA) structures in the cell tissues of bacteria, viruses, parasites, algae, and other pathogenic microorganisms in the water are destroyed, thereby killing various bacteria and viruses without using any chemical drugs. Even in slightly polluted water environments, nitrate is not converted into nitrite.

![]()

Scope of application of equipment for removing nitrite from mountain spring water and mineral water:Removal of excessive nitrite and bromate in mountain spring water and mineral water

Common matching mountain spring water and mineral water treatment processes:Mineral water, mountain spring water→ Water storage tank→ Boosting pump→ Sand filter→ Activated carbon→ Precision filters→ UV sterilizer→ Ultrafiltration→ Aseptic water tank→ Nitrite removal device→ bottling

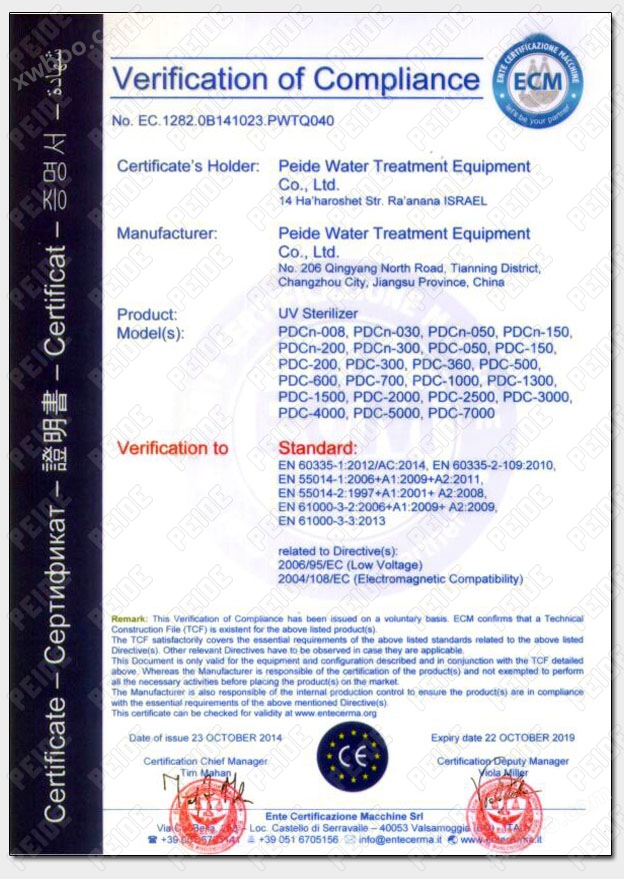

Received EU CE certification:

On site case of nitrite removal equipment for mountain spring water and mineral water:

[Customer] Ningbo Simingshan Mineral Water Co., Ltd

【 Application 】 Removal of Nitrite in Mineral Water Production Process

【 Installation location 】 Ningbo

[Contract Number] 2027918A5

Inspection, production, debugging, and packaging of nitrite removal equipment for mountain spring water and mineral water

Analysis and Inspection of Stainless Steel Material

After purchasing raw materials for nitrite removal equipment from mountain spring water and mineral water, the testing personnel in the testing department of Peide Water Treatment Company will conduct strict testing on the raw materials. Peide Water Treatment purchased a handheld alloy analyzer at a high price (200000 yuan), which features revolutionary GOLDD technology and extremely high sensitivity and detection accuracy. Purchasing a handheld alloy analyzer can be considered an expensive investment. Peide Water Treatment focuses on product quality control, so material inspection must use good testing equipment.

Packaging diagram for the shipment of nitrite removal equipment for mountain spring water and mineral water:

Water is the source of life, and safe and clean drinking water is related to people's health. Harmful microbial communities and nitrites pose a great threat to human health.

In recent years, standards for purified water have been successively introduced, and the country has set stricter quality standards for bottled and bottled purified water. The standard specifications for purified water enable the general public to drink safe drinking water and improve the quality of life of the people.