A nozzle flowmeter is a differential pressure generating device for measuring flow rate, which can be used in conjunction with various differential pressure gauges or transmitters to measure the flow rate of various fluids in pipelines. The standard nozzle throttling device is used in conjunction with differential pressure transmitters to measure the flow rates of liquids, vapors, and gases, and is widely used in sectors such as petroleum, chemical, metallurgical, power, and light industry.

A nozzle flowmeter is a differential pressure generating device for measuring flow rate, which can be used in conjunction with various differential pressure gauges or transmitters to measure the flow rate of various fluids in pipelines. The standard nozzle throttling device is used in conjunction with differential pressure transmitters to measure the flow rates of liquids, vapors, and gases, and is widely used in sectors such as petroleum, chemical, metallurgical, power, and light industry.

Applicable medium; Specially suitable for high temperature and high pressure steam and water, and can also be used for various gases and liquids

Applicable medium; Specially suitable for high temperature and high pressure steam and water, and can also be used for various gases and liquids

·Nominal caliber:DN15-2000mm(DN>500Can also be designed and produced)

·working pressure:≦42MPa

·Working temperature:-50℃— 650℃

·Pressure tapping method: Corner joint (separate ring chamber, integrated flange ring chamber, or direct drilling) for pressure tapping

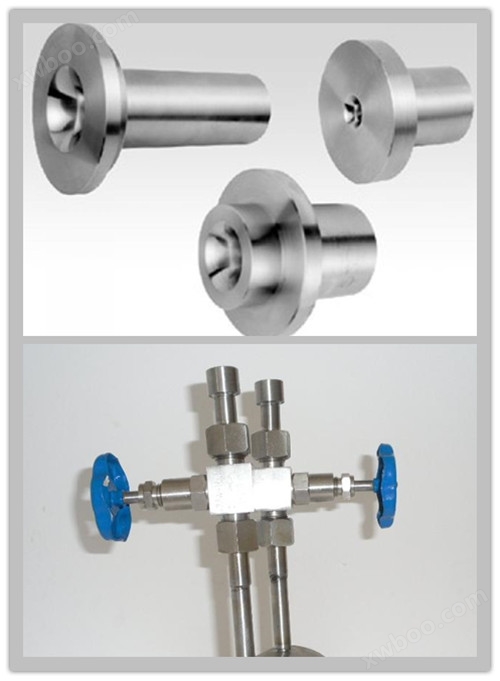

·Installation method of nozzle: flange (direct drilling and pressure tapping), fastener clamping type

Flange, ring chamber, fastener clamping type

Clamp (also pressure piece) welded type

·Execution standards: IS05167; GB/T2624

·accuracy:Compliant with standards:±1.0 %

·Material: Flanges or clamps: Carbon steel or alloy steel can be selected according to the medium temperature; Stainless steel, etc

spurt mouth:stainless steel304; three hundred and sixteenclass

1The structure of the nozzle flowmeter throttling device is easy to replicate, simple and sturdy, with stable and reliable performance, long service life, and low priceLian.

2The nozzle calculation adopts international standards and processing.

3The nozzle flowmeter has a wide range of applications, and can measure all single-phase flows, as well as some mixed phase flows.

4High precision and comprehensive self diagnostic function. The range of the intelligent standard nozzle flowmeter can be self programmed and adjusted.

5In addition to online and dynamic full compensation functions, the nozzle flowmeter also has self diagnosis and self setting range.

1、Our company promises that if anyone purchases our products, oneDuring the annual warranty period, if we receive notification from users about such defects, our company will provide unconditional free repair or replacement for products that are indeed defective.

2. We promise to handle the customer's technical questions within one working day.

3. We promise to return the instruments for repair to the factory3Provide test results within working days,7Complete the repair within one working day.

4. After returning the instrument to the customer2Follow up with users within the week and provide free consultation on automation related technologies.