Self operated pressure regulator

The self operated pressure regulator maintains a constant pressure difference through the external needle valve based on the principle of force balance to maintain a constant fluid flow rate through the external needle valve. The self operated pressure regulator is connected to the external needle valve and downstream feedback pipeline to form a closed-loop automatic control system. The constant pressure difference before and after the needle valve is determined by the load spring on the inner membrane of the controller, and the pressure difference above and below the membrane is made equal to the pressure difference before and after the needle valve through the feedback pipeline from behind the needle valve to the membrane.

Self operated pressure regulators (constant current regulators) are used in situations where the medium pressure fluctuates greatly, to control the flow rate of gases and liquids to remain constant, so that flow meters can obtain stable and accurate measurements. They can be widely used for blowing (gas) at various analytical instruments, orifice plates, and other pressure taps. RE type is used to stabilize changes in inlet gas or liquid pressure (also applicable to changes in outlet pressure for liquids). RA type is only used for gas, stabilizing outlet pressure changes.TZLM-01 Self Operated Flow Regulator

A self operated flow regulator is a flow control instrument composed of a regulator and a glass rotor flowmeter. It does not require external kinetic energy and relies on the energy of the fluid itself to stabilize the pressure of the measured fluid, thereby achieving flow control and measurement. It can be widely applied in situations where the measured fluid pressure has significant changes.

1. Main technical parameters

(1) Control and measurement range:

Water (20 ℃) 0.15-160L/h

Air (1.013 × 10 5 Pa, 20 ℃) 3-1600L/h

(2) Range: 10:1

(3) Accuracy level: 2.5; four

(4) Adjustment performance: Input pressure changes by ± 10%, output flow changes by less than ± 1%

(5) Working conditions: temperature 0-60 ℃, relative humidity<80%

2. The model specifications are shown in Table 1

Table 1

model

Measure fluid

Control and measurement

rangeaccuracy

gradeAllow the measured fluid condition size in millimeters

Temperature ℃

Pressure MPa

A

B

C

D

TZLM-01-Q1

gas

0.05 ~ 0.5L/min

0.1 ~ 1L/min

0.15 ~ 1.5L/min

0.2 ~ 2L/min

4

0 ~ 60

0.02 ~ 0.15

26

21

-

-

gas

0.3 ~ 3L/min

0.5 ~ 5L/min

0.7 ~ 7L/min

1 ~ 10L/min

1.5 ~ 15L/min

29

30

TZLM-01-Q2

gas

16 ~ 160L/h

25 ~ 250L/h

40 ~ 400L/h

60 ~ 600L/h

100 ~ 1000L/h

2.5

0.03 ~ 0.25

36

43.5

171

180

160 ~ 1600L/h

250 ~ 2500L/h

0.05 ~ 0.25

43

224

253

TZLM-01-Y1

liquid

2.5 ~ 25ml/min

6 ~ 60ml/min

4

0.03 ~ 0.15

26

21

-

-

TZLM-01-Y2

1 ~ 10L/h

1.6 ~ 16L/h

2.5 ~ 25L/h

4 ~ 40L/h

6 ~ 60L/h

2.5

0.03 ~ 0.25

36

43.5

171

180

10 ~ 100L/h

16 ~ 160L/h

43

244

253

3. The appearance and installation dimensions are shown in the following figure and Table 1

TZLM-01-Q1 TZLM-01-Y1 Self standing Flow Regulator Outline Drawing

Outline drawing of TZLM-01-Q2 TZLM-01-Y2 self-supporting flow regulator

LZCSeries blowing device

1、 Overview

The LZC series blowing device is composed of a metal tube float flowmeter and a constant flow control valve produced, which achieves constant flow output setting, control, and indication in the system. It can be widely used in process control such as blowing and differential pressure liquid level measurement of transmitters in industries such as petroleum refining, chemical industry, ethylene, fertilizer, steel, chemical fiber and textile.

2、 Measurement principle

The constant flow control valve consists of a regulating valve and a balancing control valve. The flow rate of the constant flow control valve depends on the connection

At the position of the valve on the diaphragm, when there is no medium flow, there is no differential pressure before and after the regulating valve. The diaphragm only opens the balance control valve under the force of the spring. When fluid flows through, a differential pressure P1-P2 is generated before and after the regulating valve. This differential pressure simultaneously acts on the diaphragm, opposite to the force of the spring, causing the valve to close appropriately. According to the principle of balance, the elastic force is equal to the pressure difference between the front and rear ends of the regulating valve and the pressure generated by the diaphragm, so that the medium flow rate remains constant. Change the flow setting value by adjusting the valve.

When applied to gases or vapors, due to the compressibility of gases, precise flow control is based on the pressure on the constant flow control valve as a constant value. According to the setting position of the constant flow control valve, there are two types:

The RE type flow controller is set upstream and is suitable for situations where the outlet pressure of the flow controller is a constant value or discharged into the atmosphere when gas or vapor is present.

The RA type flow controller is installed downstream and is suitable for situations where the outlet pressure of the flow controller is a constant value when using gas or vapor. When used in liquid applications, the two models have the same effect.

3、 Model Naming

LZC A – B / C / D / E

A is equipped with a flow meter

Position of B flow control valve

C User Side Connection Method

1

LZZW type metal tube float flowmeter

RE

Inlet pressure regulator

F

Flange (HG20592)

2

LZZ type metal tube float flowmeter

RA

Export pressure regulator

S

Threaded connection NPT

3

DK800 glass rotor flowmeter

K

Ferrule connection

D Contact medium material

Attachment E

RR1

1Cr18Ni9Ti

P

Equipped with pressure gauge

RRO

316

G

Equipped with a filter

RL

316L

4、 Main technical parameters

model

LZC1

LZC2

measuring range

Water (20 ℃)

0.3-100L/H

2.5-4000L/H

Air (20 ℃ 101325Pa)

5-3400L/H

0.07-110m3/h

Range ratio

10:1

Accuracy class

Level 4

Level 2.5

Flow scale division

Actual flow scale

Small requirement pressure difference

0.05MPa

Large controllable pressure difference

0.5MPa

Great pressure

4.0MPa or according to user requirements

medium temperature

-80+150 ℃

ambient temperature

-25+65 ℃

Contact medium material

304 316 316L and PTFE gaskets

casing

Aluminum casting, epoxy resin spraying

connect

Standard thread

1/4 "NPT or 1/2" NPT female thread

1/2 "NPT or 1" NPT female thread

Standard card sleeve

Φ 6 、φ 8 、φ 10mm

φ 12mm

Standard flange

HG20592-97 DN15, DN25 or according to user requirements

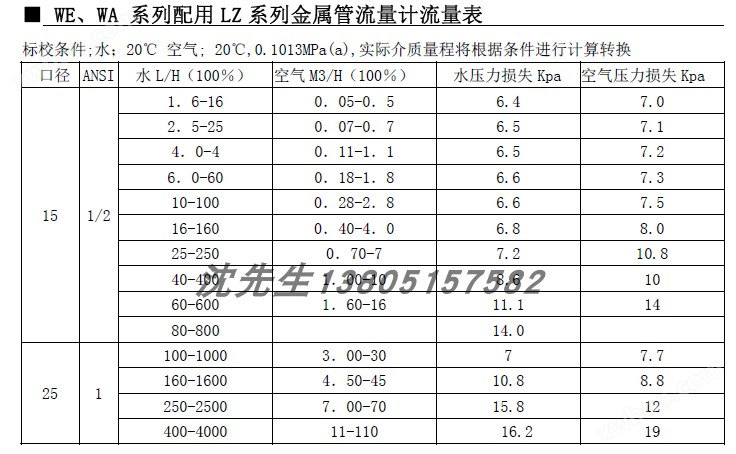

5、 Measurement range

1. LZC1 type blowing device

Cone tube number

water

( 20 ℃ L/H )

air

( 20 ℃ 101325Pa L/H )

High pressure loss (KPa)

W01

--

1.2-12

1.0

W02

--

5-50

1.2

W03

0.3-3

10-100

1.4

W04

0.5-5

15-150

1.5

W05

1-10

40-400

1.8

W06

2.5-25

80-800

3.5

W07

4-40

125-1250

6.5

W08

6-60

200-2000

13.0

W09

8-80

250-2500

23.5

W10

10-100

340-3400

40.0

2. LZC2 type blowing device

Diameter DN (mm)

Flow range

High pressure loss

Air (20 ℃ 101325Pa) m3/h

Water (20 ℃) L/H

Attributes [Origin] Chinese Mainland [Flow meter type] rotameter