1Equipment principle and composition:

AUK-CIO electrolytic salt method sodium hypochlorite generator is a type of electrolytic dilution method that uses non membrane electrolysisSodium chloride(A device for producing sodium hypochlorite solution from NaCl aqueous solution. The equipment consists of an electrolytic cell, an electrolytic power supply, a salt dissolution box, a dilute salt box, a storage box, a dosing device, and inlet and outlet pipelines.

The electrolytic power supply adopts a voltage not exceeding24V or 36V DC power supply. In an electrolytic cell with special electrode plates (titanium based coated rare metal oxides of ruthenium, rhodium, iridium, and platinum), dilute salt water with a predetermined concentration is electrolyzed to produce sodium hypochlorite solution. The disinfectant dosing system automatically adds the sodium hypochlorite solution generated by the equipment to the water to be disinfected for disinfection.

The total electrochemical reaction of the electrode is expressed as follows:

NaCl+H2O→NaClO+H2↑

Electrode reaction:

Anode:2Cl- -2e→Cl2

Cathode:2H++2e→H2

Solution reaction:2NaOH+Cl2→NaCl+NaClO+H2O

Product schematic diagram

Product Composition Structure Diagram

IIScope of Equipment Application

IIIequipment installation

1. As the equipment is a live device, it must be installed and used indoors to avoid rain and sun exposure. Indoor temperatureDegree rangeFrom 0 ℃ to 45 ℃, if it exceeds this range, indoor heating and cooling facilities should be added. The air is relatively humidDegree not greater than85% and well ventilated.

2. There must be tap water with a pressure of 0.15Mpa to 0.45Mpa and a diameter of DN15-DN50 in the equipment roomEquipment water supply.(The water pressure and pipe diameter vary depending on the size of the device model)

4. There is no direct sunlight, no severe vibration, good ventilation, no flammable or explosive dust, and no corrosion in the equipment roomGases that corrode metals and damage insulation.

5. There must be a power supply installed in the equipment room, and the equipment uses a voltage of 220 volts or 380 volts; Equipment model less thanWhen the voltage is below 800, use 220 volts. When the equipment model is greater than 800 (including 800), use electricity Press for380 volts. Using power supplyIf the positive or negative voltage exceedsWhen 10% of the situation occurs, please inform yourself in advanceVoltage stabilizing device.

6. The equipment uses refined edible salt, and the sodium chloride content is not less than 97%.

7. The net area between devices should reach 6-25 square meters (installation area varies depending on the size of the device model)Different).

8. Our company's installation project is limited to indoor installation construction. Please install outdoor trench and pipe laying projects in advanceArrange for preparation; The diameter of the outdoor disinfectant dosing pipeline should be equal to the diameter of the indoor water supply pipe.

9. If the distance between equipment is more than 30 meters from a water well or clean water tank, and the ground level between equipment is lower than that of the clean water tankWhen adding mouth, please bring your own not less thanA pipeline pump with a lift of 30 meters.

4、 Characteristics

The electrolytic salt method sodium hypochlorite generator of Shanghai Aoke Environmental Technology Co., Ltd. is a disinfection equipment with multiple unique patented technologies developed in the "948" introduction and promotion project of the Ministry of Water Resources, based on the reference of advanced foreign technology and combined with actual domestic usage conditions.

① Unique electrode descaling technology, no acid washing and maintenance required:

The electrode adopts a unique coating technology that can adapt to frequent reverse polarity for descaling. At the same time, the electrode works symmetrically in both forward and reverse directions, which solves the problem of efficiency decline or malfunction caused by continuous scaling during long-term use of the electrode. At the same time, it avoids the electrode acid washing system that is necessary for traditional equipment of this kind, so that the electrode does not require special maintenance during use.

② Adopting the latest structural design from abroad, with a compact size:

The electrode adopts a new type of rectangular structure with pure series connection, and a micro scale removal device is installed at the bottom of the electrolytic cell. This reduces the volume of the entire electrolytic cell to one-third of the traditional method. In addition, the acid washing device without the electrode is removed, making the main unit of the equipment very compact. The miniaturization of volume makes equipment very convenient for transportation, installation, maintenance, and other aspects, and the price has also significantly decreased compared to traditional methods.

③ Fully automatic precise dosing:

The control center PLC of the equipment comes with 4-20 mA and RS485 input modules, which can be directly connected to the output signals of the online residual chlorine monitoring instrument and flow meter (one or several) of the water plant. According to the changes in the residual chlorine value of the factory water and the actual water supply, the dosage of disinfectant can be adjusted in a timely manner to ensure that the residual chlorine value of the factory water is always stable within a reasonable range, thereby avoiding the odor or insufficient dosage of disinfectant caused by excessive dosage at the user end.

At the beginning of equipment operation, a disinfectant dosage is initially set based on the actual flow rate and water quality. Then, according to the measured residual chlorine value in the factory water, if it is too high (or too low), the disinfectant dosage is reduced (or increased), so that the residual chlorine value in the factory water gradually reaches the range required by the specifications.

System automatic closed-loop control precise dosing process diagram

④ Remote monitoring:

The device comes with a remote transmission module, which can achieve remote automatic monitoring of disinfection equipment as long as it is equipped with a regular mobile phone card. The administrator can also monitor the working status of the device at any time through their mobile phone.

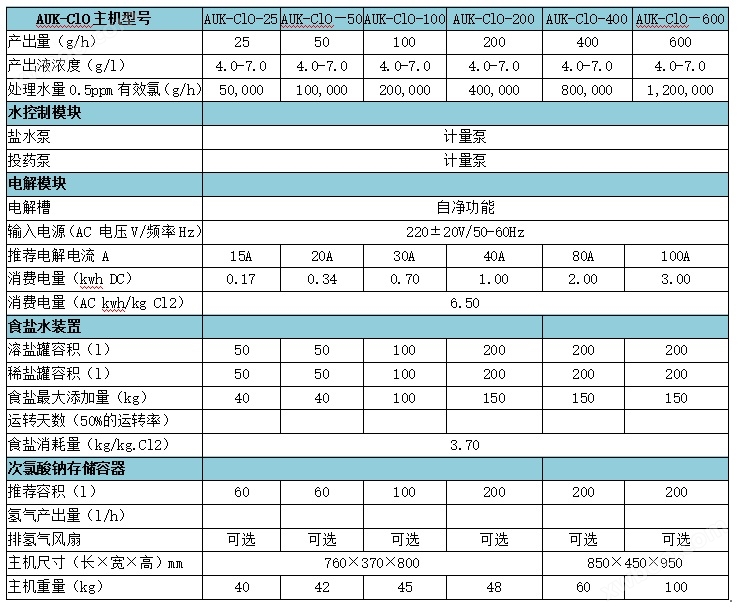

Main technical parameters and indicators(model:25~600 g/h)

Power supply voltage(V):AC220.

Inlet pressure(bar):1-3.

Dilute saltwater concentration(g/L):2.5-3.5%.

Effective chlorine concentration(g/L):3000-7000ppm.

Salt consumption(kg/kg):≤3.6.

Power consumption(kw.h/kg):≤5.6.

Operating costs(divide):≤0.85(According to effective chlorine1.0mg/LDosing).

Electrode material:1mmThick titanium electrode plate.

Electrode coating: coated with ruthenium and iridium, with the same positive and negative electrodes.

Electrode maintenance method: symmetrical reversal of positive and negative electrodes, no need for acid washing and descaling.

Service life of electrode coating:5-8Year, can be repeatedly coated and reused.

Service life of electrode plate: 8Years or more.

Whole machine design service life: 8Years or more.

Device operation panel displayLCD touch screen,Fully automatic panel control is available.

Control mode: Hand to body integrated, capable of automatic switching.

Soft water device: Yes, hardness treatment≤ 8mmol/L, effluent hardness ≤ 0.03mmol/L.

Dilute salt water preparation method: fully automatic preparation.

Dilute salt water storage tank: Yes.

Salt dissolution device: accelerates salt dissolution, saturates salt water, and mixes more evenly.

Generator working mode: Fully automatic control can work continuously without interruption.

Medication control method: Variable frequency dosing, can access online residual chlorine and flow monitoring dataThus achieving precise closed-loop control and feeding.

Remote monitoring: Comes with a wireless remote transmission module.