VIP member

Synchronous Thermal Analyzer STA 2500 Regulus

Synchronous Thermal Analyzer STA 2500 Regulus

Product details

Excellent performance

STA 2500 Regulus has efficient and reliable performance, with a wide temperature range.

Top mounted sample, unique self compensating differential balance design

The instrument is a top loading system with natural gas flow, which can automatically protect the balance from condensation deposition and contamination. This tailor-made microbalance system eliminates the effects of buoyancy and convection, making the operation simpler.

STA 2500 Regulus has efficient and reliable performance, with a wide temperature range.

Top mounted sample, unique self compensating differential balance design

The instrument is a top loading system with natural gas flow, which can automatically protect the balance from condensation deposition and contamination. This tailor-made microbalance system eliminates the effects of buoyancy and convection, making the operation simpler.

Diverse types of atmosphere

Measurement can be carried out under inert atmosphere, oxidizing atmosphere, and vacuum conditions. The atmosphere can be dynamic or static. The built-in Mass Flow Controller (MFC) is controlled by software and can change and record gas flow rate at any time according to testing needs.

Suitable for analyzing escaping gases

The top loading design of STA facilitates connection to gas analysis systems such as FTIR (Fourier Transform Infrared Spectrometer), MS (Mass Spectrometer), or GC-MS (Gas Chromatography Mass Spectrometry). At the same time as conducting thermal analysis, simultaneous analysis of the composition of the escaping gas can be carried out.

Measurement can be carried out under inert atmosphere, oxidizing atmosphere, and vacuum conditions. The atmosphere can be dynamic or static. The built-in Mass Flow Controller (MFC) is controlled by software and can change and record gas flow rate at any time according to testing needs.

Suitable for analyzing escaping gases

The top loading design of STA facilitates connection to gas analysis systems such as FTIR (Fourier Transform Infrared Spectrometer), MS (Mass Spectrometer), or GC-MS (Gas Chromatography Mass Spectrometry). At the same time as conducting thermal analysis, simultaneous analysis of the composition of the escaping gas can be carried out.

STA 2500 Regulus - Technical specifications

• Temperature range: Room temperature to 1100 ° C/1600 ° C (two easily replaceable furnace bodies)

Heating rate: 0.001 100 K/min / 0.001 ... 50 K/min

• Temperature accuracy: 0.3 K

• Weighing range: ± 250 mg

• Sample size: maximum 1 g

• Thermogravimetric resolution: 0.03 μ g

Thermocouple: S-type

• Vacuum tightness: up to 10-4 mbar (10-2 Pa)

• Atmosphere: Inert, oxidizing, vacuum

• Gas control: Built in mass flow controller

• Temperature range: Room temperature to 1100 ° C/1600 ° C (two easily replaceable furnace bodies)

Heating rate: 0.001 100 K/min / 0.001 ... 50 K/min

• Temperature accuracy: 0.3 K

• Weighing range: ± 250 mg

• Sample size: maximum 1 g

• Thermogravimetric resolution: 0.03 μ g

Thermocouple: S-type

• Vacuum tightness: up to 10-4 mbar (10-2 Pa)

• Atmosphere: Inert, oxidizing, vacuum

• Gas control: Built in mass flow controller

STA 2500 Regulus - Software Features

The measurement and analysis software for STA 2500 Regulus is based on Microsoft Windows®Proteus of the system®The software package includes all necessary measurement and data analysis functions. This software package has an extremely user-friendly interface, including easy to understand menu operations and automated workflows, and is suitable for various complex analyses. Proteus software can be installed on the control computer of the instrument for online operation, or installed on other computers for offline use.

Thermogravimetric analysis:

TGA curve, displayed in the form of absolute mass change (mg) or relative mass change (%)

Automated quality change steps and characteristic temperature analysis

Extrapolation starting and ending point analysis

Peak temperature, first-order differentiation, second-order differentiation

TGA stability check

• Rate controlled weightlessness

Calorimetry:

Measure thermal effects in units of uV, uV/mg, or mW/mg

Analyze the starting point, peak temperature, inflection point, and termination point of thermal effects

• Automatic peak search

• Optional direction for heat absorption and release (compatible with DIN or ASTM standards)

• Conversion rate calculation

The measurement and analysis software for STA 2500 Regulus is based on Microsoft Windows®Proteus of the system®The software package includes all necessary measurement and data analysis functions. This software package has an extremely user-friendly interface, including easy to understand menu operations and automated workflows, and is suitable for various complex analyses. Proteus software can be installed on the control computer of the instrument for online operation, or installed on other computers for offline use.

Thermogravimetric analysis:

TGA curve, displayed in the form of absolute mass change (mg) or relative mass change (%)

Automated quality change steps and characteristic temperature analysis

Extrapolation starting and ending point analysis

Peak temperature, first-order differentiation, second-order differentiation

TGA stability check

• Rate controlled weightlessness

Calorimetry:

Measure thermal effects in units of uV, uV/mg, or mW/mg

Analyze the starting point, peak temperature, inflection point, and termination point of thermal effects

• Automatic peak search

• Optional direction for heat absorption and release (compatible with DIN or ASTM standards)

• Conversion rate calculation

STA 2500 Regulus - Application Examples

Rubber carbon black content testing - good reproducibility

The carbon black content of rubber materials is very important in the quality control process. In this example, three samples were taken from the same batch of rubber mixture for carbon black content testing. The decomposition was monitored under an inert atmosphere, and when the decomposition was completed and switched to air, the average weight loss ratio of carbon black was measured to be 0.282 ± 0.006%. This result reflects the reliability and good repeatability of the STA 2500 Regulus.

Rubber carbon black content testing - good reproducibility

The carbon black content of rubber materials is very important in the quality control process. In this example, three samples were taken from the same batch of rubber mixture for carbon black content testing. The decomposition was monitored under an inert atmosphere, and when the decomposition was completed and switched to air, the average weight loss ratio of carbon black was measured to be 0.282 ± 0.006%. This result reflects the reliability and good repeatability of the STA 2500 Regulus.

Testing of three rubber samples from the same batch. The atmosphere switched from nitrogen to air. Heating rate 20K/min, Pt crucible.

The phase transition of iron

The phase transition of iron

The high sensitivity DTA of STA 2500 Regulus can detect weak phase transitions. In addition, a pure atmosphere can be obtained through the vacuum pumping and filling of an automatic vacuum device. The right figure shows the measurement of pure iron samples on STA, with a temperature range from room temperature to 1600 ℃. On the blue DTA curve, the thermal effect at 744 ℃ is due to the magnetic transformation of the material. The endothermic peaks with peak temperatures of 908 ℃ and 1389 ℃ indicate the occurrence of crystal transformation. The endothermic peak at 1533 ℃ is melting. There is no weight change on the TG curve, indicating that the system has good sealing performance and can ensure the purity of the inert atmosphere.

STA test for pure iron, with a heating rate of 20K/min. The vacuum sealing design of the system ensures that high-purity iron is completely free of oxidation,

Thus, the phase transition on the blue DTA curve was measured without any change in the green TG curve.

Thus, the phase transition on the blue DTA curve was measured without any change in the green TG curve.

Sublimation of OEL coating

Multilayer organic structures have special optical and physical properties and can be used in optoelectronic devices such as organic light-emitting diodes (OLEDs). In organic multilayer structures, α - NPD is a porous transport material. The vacuum sealed structure of STA 2500 Regulus allows samples to be tested under reduced pressure conditions. Under normal pressure, α - NPD begins to sublime at 380 ℃ (blue curve), while under reduced pressure conditions, the sublimation starting temperature of the sample decreases and begins to sublime at 240 ℃ (red curve).

Comparison of α - NPD testing under normal and reduced pressure

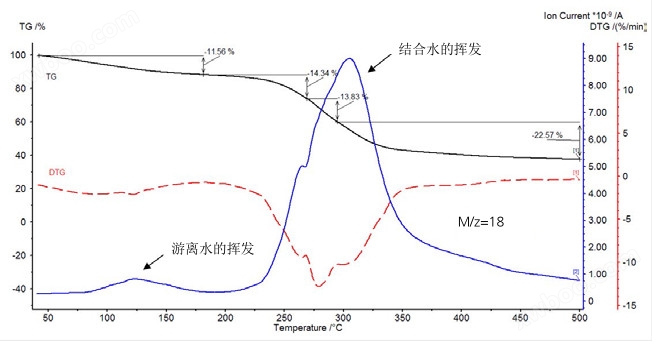

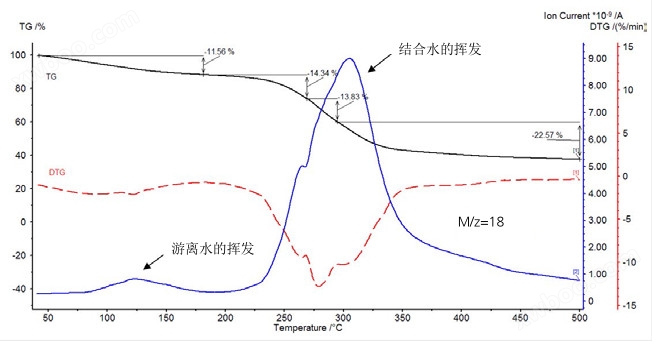

Testing of capsules in cigarette filters

Recently, the tobacco industry has adopted a new technology to make cigarettes more attractive. This technology involves embedding a capsule filled with seasoning liquid into the filter mouth of a cigarette. This capsule can change the taste of tobacco or keep it moist. The left figure shows the measurement results of thermogravimetric and mass spectrometry in the range of 50 to 500 ℃ for the immersed capsule. The evaporation of water has multiple weight loss steps (black TGA curve and red DTG dashed line), which can be confirmed from the signal of MS mass number 18. Thanks to the balance being able to quickly reach stability before measurement, it is possible to detect the evaporation of free water before the release of bound water.

TG-MS measurement of capsules

STA 2500 Regulus - Related attachments

Sample tray, crucible, and nested platform

Sample tray, crucible, and nested platform

The instrument can be equipped with crucibles made of various materials such as alumina, platinum, aluminum, quartz, etc., and has different shapes and sizes to choose from. The STA 2500 Regulus comes standard with a nested platform that supports almost all crucible types. A large volume crucible requires a larger fitting platform.

Used in conjunction with an escaping gas analyzer

By combining the STA 2500 Regulus with gas analysis systems such as FT-IR (Fourier transform infrared spectrometer), QMS (quadrupole mass spectrometer), or GC-MS (gas chromatography-mass spectrometer), information on the types of gases emitted from the sample at different times/temperatures can be obtained. From this, more detailed information about the tested material can be obtained, and even characteristic information about the material composition may be obtained.

Used in conjunction with an escaping gas analyzer

By combining the STA 2500 Regulus with gas analysis systems such as FT-IR (Fourier transform infrared spectrometer), QMS (quadrupole mass spectrometer), or GC-MS (gas chromatography-mass spectrometer), information on the types of gases emitted from the sample at different times/temperatures can be obtained. From this, more detailed information about the tested material can be obtained, and even characteristic information about the material composition may be obtained.

Online inquiry