Excellent synchronous thermal analysis performance

The balance system can provide sufficient sample size and measurement range (up to 35g), while also having high resolution (0.1 μ g) and low drift (within μ g amplitude). Combined with high sensitivity DSC performance, it can perform various sample tests over a wide temperature range.

Unique combination - accurate TGA-DSC and large capacity TGA

Within a wide temperature range of room temperature to 1600 ° C, STA449F5 ® High precision and high repeatability TGA and DSC measurements can be performed. TGA supports large-scale sample testing, with a maximum crucible volume of up to 5 cm3.

Top mounted sample - mature thermal balance design scheme

STA 449 F5 Jupiter®The top loading structure is adopted, which has long been the standard method for balance measurement in the laboratory. The reason is simple, this design combines the characteristics of superior performance and simple operation.

STA 449 F5 Jupiter®-Technical parameters (continuously updated)

• Temperature range: RT... 1600 ° C (sample temperature)

• Furnace body: SiC furnace body, motor-driven automatic lifting, easy and safe operation

Heating rate: 0.001 50K/min

• Sensors:- TGA-DSC (standard configuration) - TGA-DSCASC (optional, suitable for configurations with automatic sampler) - TGA (optional, for large sample volumes) - TGA-DTA (optional)

Users can quickly and conveniently replace different sensors themselves

• Vacuum tightness: 10-2 mbar

AutoVac: an integrated software controlled automatic vacuum system

• Atmosphere: Inert, oxidizing, static, dynamic

Automatic Sample Injector (ASC): 20 crucible positions (configuration II)

Gas flow control: Integrated with 3 mass flow meters (1 protective gas, 2 purge gas)

• Temperature resolution: 0.001 K

• Balance resolution: 0.1 μ g (full range)

• BeFlat ®: Built in, automatically adjusts buoyancy effects related to crucible type, atmosphere, heating rate, and other factors to obtain a smooth baseline

• Balance drift:< 5 μg / h

• Maximum sample weight: 35000 mg (including crucible), corresponding to TGA measurement range

• Sample volume: maximum 5 cm3 (for TGA crucible)

• Enthalpy accuracy: 1% (In)

• Analysis of emitted gases: QMS, GC-MS and/or FT-IR combined

STA 449 F5 Jupiter®The measurement and analysis software is based on Windows®Proteus of the system®Software package. The software itself is self-contained and does not require complex custom configuration. The software has a very user-friendly interface, automated programs, and context sensitive help systems that can help you reduce workload and save time. Proteus®Associated with each specific instrument and can also be installed on other computers.

Conventional software features

Multi tasking: capable of simultaneously performing measurement and data analysis

Multiple modules: using the same computer to operate different instruments

• Comprehensive analysis: Compare and analyze STA, DSC, TGA, DIL, TMA, and DMA measurements in the same spectrum

• Adjustable coordinate range

• Visualization and data export

Calculate first-order and second-order differentials, including peak temperature

• Storage and Recovery Analysis Status

• Context sensitive help system

The software is developed and designed by a professional subsidiary company certified by ISO

DSC related characteristics

Measure the starting point, peak temperature, inflection point, and termination temperature, and perform automatic peak search

Analyze the peak area (enthalpy) of heat release and absorption, and provide multiple baseline types to choose from; Support partial peak area analysis

• Comprehensive analysis: Compare and/or analyze multiple measurement curves such as STA, DSC, TGA, DIL, TMA, DMA, etc. in the same spectrum

Comprehensive analysis of glass transition temperature

• Crystallinity

OIT (oxidation induction time)

• Specific heat measurement (optional)

TGA related characteristics

• Quality change, unit:% or mg

Automatically analyze quality change steps, including residual quality analysis

The starting and ending points of extrapolation

• Automatic baseline correction function (TGA BeFlat)®), used for automatic correction of measurement influencing factors

• c-DTA®Computational DTA signal, analyzing characteristic temperature and peak area (optional function for single TGA measurement)

• Super-Res®: Rate control quality change (optional)

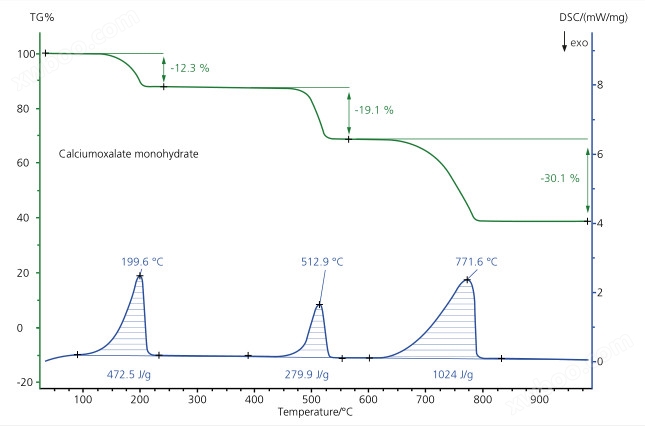

Calcium oxalate monohydrate

The following figure shows the TGA and DSC curves of CaC2O4-H2O in the temperature range of room temperature to 1000 ℃. The first stage of weight loss is the dehydration process, where the sample transforms into anhydrous calcium oxalate (CaC2O4) after dehydration. The second stage of weight loss step is caused by the release of CO, representing the transition from calcium oxalate to calcium carbonate (CaCO3). At temperatures above 700 ℃, calcium carbonate decomposes and releases CO2; The residual mass is calcium oxide (CaO). The experimentally measured weight loss is in good agreement with the theoretical value (deviation<1%). This proves that STA 449 F5 Jupiter®Thermobalance has high measurement accuracy.

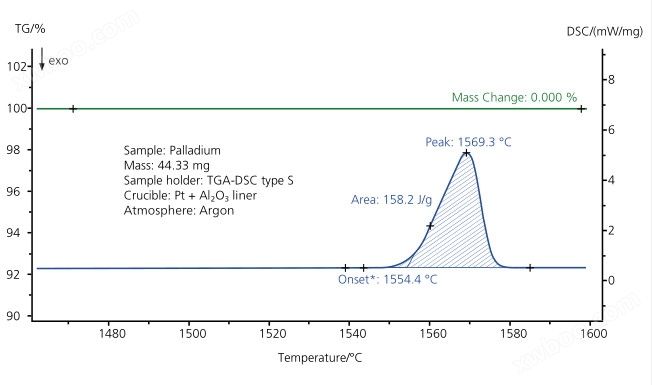

The melting point of palladium

The biggest use of palladium (Pd) today is as a catalytic converter. In addition, it is often used in other fields such as dentistry, aircraft spark plugs, surgical instruments, electrical contact materials, etc. Palladium does not react with oxygen at room temperature, but when heated to 800 ° C in an air atmosphere, it forms a very thin layer of palladium (II) oxide (PdO). This figure shows the measurement of Pd conducted on STA, with a maximum temperature of 1600 ° C. The blue DSC curve shows the melting process, with a enthalpy of 158 J/g and a melting starting point of 1554 ° C. These two values are very close to the theoretical values of pure Pd, with a deviation of<1%. The green TG curve shows that there was no weight loss before and after melting; This proves the high purity of the metal and the vacuum tightness of the system.

Pd sample testing, weighing 44.33mg, heating rate 20K/min

Thermogravimetric testing of weathered rocks

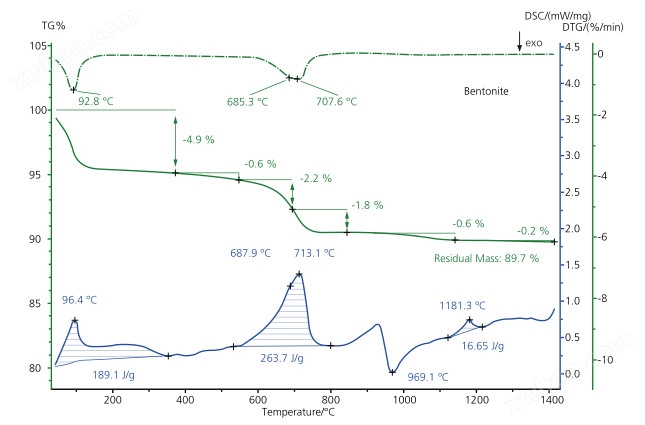

Bentonite is a type of clay mainly composed of Jiaoling stone, which is praised for its adsorption ability. This mineral material is often used in fields such as adhesives and purifiers. The green curve in this figure represents TG, the green dotted line represents DTG, and the blue curve represents DSC curve. The first weight loss step (DSC peak temperature of 96 ℃) is caused by the release of water, followed by a small weight loss process of 0.6%, which is likely caused by the cracking of organic impurities, indicating the presence of a small amount of pyrite impurities in the material. Above 600 ℃, water is released from the porphyritic rock structure (DTG peak temperatures of 685 ℃ and 708 ℃). The exothermic peak of the DSC curve at 969 ℃ represents the phase transition of the mineral. The most likely reason for the endothermic peak at 1181 ℃ is partial melting.

Complex thermal behavior of porphyritic rocks, heating rate 10K/min, atmosphere N2 (70ml/min), crucible Pt

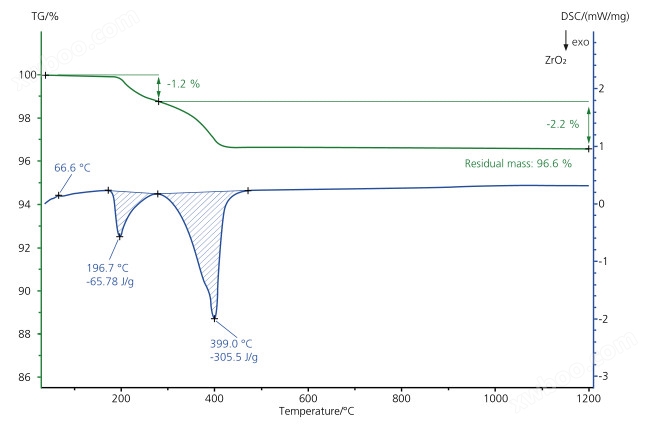

Zirconia adhesive burned out

The measurement temperature range in the following figure is from room temperature to 1200 ℃, and the green curve is the TG curve. There are two small weight loss processes before 450 ℃, with a total weight loss of 3.4%, which is consistent with the two exothermic peaks at 197 ℃ and 399 ℃ on the blue DSC curve. These effects are caused by the burning out of binders in ceramic materials, resulting in higher calorific values and larger peak shapes. The small DSC endothermic peak near 67 ℃ is caused by the melting of the adhesive.

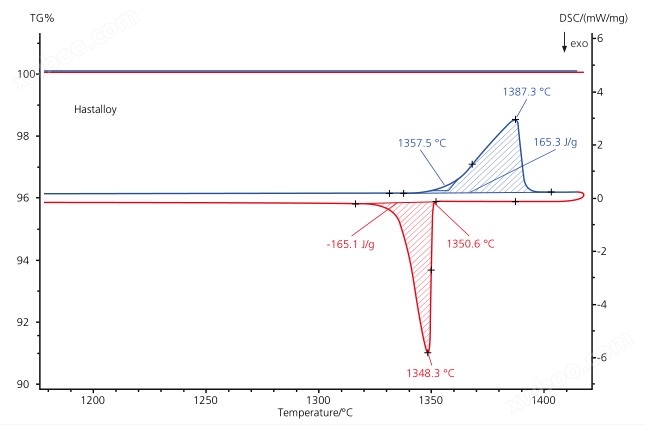

Corrosion-resistant alloy

Hastelloy is a nickel chromium molybdenum tungsten alloy that exhibits excellent high-temperature stability and good ductility and corrosion resistance even at high temperatures. It is often used in combustible gas desulfurization, chemical industry, and burn sterilization. The heating DSC (blue) curve in the figure shows that the melting of Hastelloy sample (alloy 22) occurred at 1358 ℃ (extrapolated starting point) with a enthalpy of 165J/g. The cooling DSC (red) curve shows that the crystallization process occurs at 1351 ℃ (extrapolated starting point), and its enthalpy change is almost identical to the melting process. The TG curves for temperature rise and fall are all horizontal lines, and no weight loss or weight gain caused by oxidation was observed.

Temperature rise and fall testing of Hastelloy samples. Weigh 39.02mg, heating and cooling rate 20K/min, Ar atmosphere, 70ml/min; Used Pt crucible with Al2O3 lining

Two methods, a more effective combination

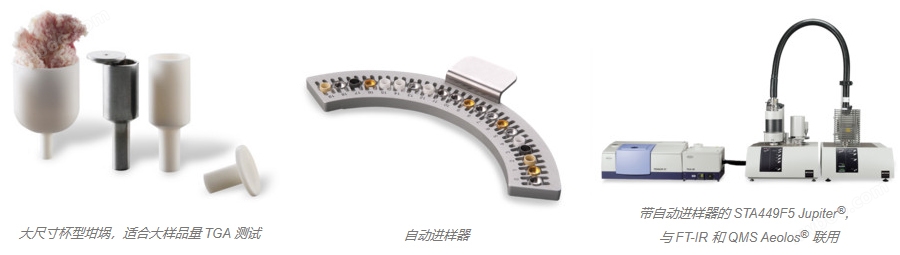

The system is equipped with user replaceable TGA-DSC sensors that can perform DSC, synchronize TGA-DSC measurements, or use ASC for automatic sampling. In addition, TGA and TG-DTA sensors are also provided.

Atmosphere - Perfectly controlled using MFC and AutoVac

Three built-in mass flow controllers can optimally control the blowing gas and protective atmosphere around the sample. The use of vacuum pumping and inert atmosphere replacement can further control the atmosphere around the sample, and can also handle powder samples and other difficult to vacuum samples perfectly. This AutoVac device simplifies the operation of the vacuum process. The device includes a vane rotary pump system that can be fully operated through software.

We offer crucibles of various materials and sizes. The most common crucible materials include alumina and platinum. There are also crucibles made of other materials, such as gold, zirconia, etc. The crucible can be equipped with a perforated or unperforated crucible cover. With such a wide range of choices, there is always one that meets your testing requirements.

The automatic sampler provides up to 20 sample grades, which can be used for TGA or TGA-DSC measurements. The automatic sampler ensures the optimal injection position and maximum processing capacity of the sample. By pre writing the injection sequence, it is possible to fully utilize the evening or weekend time, and the instrument will measure according to the pre programmed schedule.

Efficient and reliable - a choice you won't regret

STA 449 F5 (including versions equipped with automatic injectors) can be used in conjunction with QMS, FTIR, or GC-MS to analyze the composition of emitted gases. The instrument can also be simultaneously connected to QMS and FTIR, or GC-MS and FTIR.