VIP member

Temperature control unit (pulse type)

Temperature Controller: Each sterile packaging, clean packaging, toxic and hazardous packaging, etc. must meet the heat sealing requirements

Product details

German Audion

Temperature control unit (pulse type)

Temperature Controller

Each sterile packaging, clean packaging, toxic and hazardous packaging, etc. must meet the requirements for heat sealing to prevent contamination. The contamination of sterile or dust-free (operating) environments is a significant risk that needs to be avoided at all times. Even the best operators using the best packaging materials cannot guarantee the consistency of sealed packaging quality unless the heat sealing is verifiable.

We have developed a Temperature Controller for the market that has strict requirements for verifying sealing processes. Choosing different access levels is crucial for the verification type sealing process. Using Audion Touch software technology, administrators can create and save their own validated 'sealing formulas'. The operator operating the machine can only choose those pre made "sealed formulas".

When you set the desired temperature on the controller (ADC), the temperature system (ATC) sends a certain amount of energy output to the sealing line. The system adjusts the temperature by measuring the resistance of the sealed wire circuit.

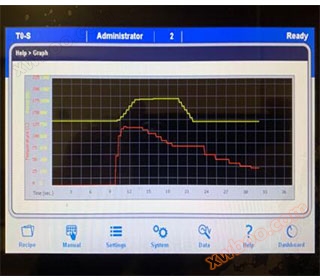

Temperature is the most important factor, but we also control and monitor other factors such as sealing time and sealing pressure. In this picture, you can see the entire sealing process.

The figure shows the entire sealing cycle, from heating, sealing rod closure and sealing, to finally cooling and opening of the sealing rod. The blue line represents temperature, and the red line represents pressure. Firstly, the temperature inside the sealing rod begins to rise. After reaching the appropriate temperature, the sealing rod closes and the sealing time begins to be calculated. The system measures the average temperature and average force until the program sealing time ends. Afterwards, the temperature will cool to the set cooling temperature, and once it reaches the set value, the sealing rod will open.

The Temperature Controller provides complete process monitoring of sealing temperature, sealing force (pressure), and effective sealing time. The ISO 11607-2 standard for process monitoring is related to the validation of sealing processes. The key process parameters of the pulse sealing machine are sealing temperature, sealing force (pressure), and sealing time. These parameters need to be controlled and monitored. The monitored process parameters mean that it must have an alarm function. The heat sealing device equipped with a Temperature Controller is equipped with alarm functions for all three parameters.

Online inquiry