Security Warning

Proper use according to the instructions in the manual can prevent unnecessary malfunctions or damage to the product and ensure the safety of the user.

1. Safety precautions that may pose a danger to the operator during use.

2. Personal maintenance, adjustment, or replacement of vulnerable parts may cause personal injury to the operator.

Please strictly follow the instructions in this manual to install and use this product for better performance.

1. Product Overview

1.1 Product Usage

NA-M70S4 is one of the series products of our company's NA. It is designed according to the technical specifications of Q/ZTT 1017-2015 Base Station AC Smart Meter by China Tower Co., Ltd. It adopts a 160 * 160 dot matrix LCD display, which can perform parameter query, setting, alarm information, manual switch control, etc. It has functions such as real-time voltage/current measurement, real-time electricity metering, power supply quality abnormal alarm, and information exchange. It is a powerful, safe and reliable three-phase four circuit measurement and control instrument, which can be widely used in communication base stations, power systems, environmental detection, low-voltage distribution and other fields.

1.2 Product Features

The NA-M70S4 three-phase electronic multi circuit smart meter has an industrial standard RS-485 communication interface and supports YD/T1363 protocol. The current CT adopts a crystal head connection, and the CT range, transformation ratio, and core direction of the instrument can be set on the panel for convenient on-site use; The battery level can be reset through password and other functions; It has telemetry, remote signaling, and remote control functions, 1 DO interface, 7 DI interfaces (3 live wire detection interfaces and 4 dry nodes), voltage and frequency limit alarm, alarm, and communication prompt. It can record 5000 historical data within 15 minutes, 1000 historical data at midnight every day, 24 meter reading data per month, and 500 historical alarms.

2. Product specifications

Table 2.1 Product Specifications

Serial Number |

type |

content |

notes |

1 |

PRODUCT MODEL |

NA-M70S4 |

|

2 |

power supply |

AC 85V-264V / DC 40V-60V |

|

3 |

reference voltage |

3×220/380V |

|

4 |

Reference current |

10A |

|

5 |

Access method |

Direct Access |

|

6 |

Instrument accuracy |

Level 1 |

|

7 |

basic function |

Three phase voltage, current, power, electrical energy, combined phase and phase separated electrical energy; Remote signaling detection and alarm; Remote signaling detection and alarm; |

|

8 |

work environment |

Working temperature: -20~60 ℃, altitude<4000m |

|

9 |

External dimensions |

96mm×96mm |

|

10 |

communication |

RS485 communication interface YD1363 protocol |

|

3. Technical parameters

Table 3.1 Product Technical Parameters

performance |

parameter |

||

Input measurement display |

voltage |

measuring range |

AC 100/250V frequency: 40-70Hz |

transformation ratio |

1-1000, Uo*Ubb<=2500V |

||

accuracy |

RMS measurement (voltage accuracy: 0.5 level) |

||

electric current |

range |

The first and second circuits are 100A; Third and fourth circuits 60A |

|

transformation ratio |

1-1000, Io*Ibb<=2000A |

||

accuracy |

RMS measurement (current accuracy: 0.5 level) |

||

input |

Adopting a 6-core crystal head connection method, the default selection is an external closed three-phase integrated transformer |

||

frequency |

Error: 0.02Hz Range: 40-70Hz |

||

active power |

Active accuracy: Level 1 |

||

reactive power |

Reactive power accuracy: Level 2 |

||

electric energy |

active electrical energy |

Accuracy: Level 1 |

|

reactive energy |

Accuracy: Level 2 |

||

power supply |

power supply |

AC 85V-264V/DC 40V-60V |

|

power consumption |

<3W |

||

Output programmable |

communication |

output interface |

RS-485 interface, two-wire system |

Communication Protocol |

YD/T 1363 protocol |

||

data format |

Can set: n81, o81, e81 verification methods |

||

COMMUNICATION RATE |

BPS: 1200, 2400, 4800, 9600, 19200 can be set |

||

pulse output |

1-4 active pulses, 1-4 reactive pulses, and second pulses |

||

LCD display |

Electrical parameter inquiry |

U、I、P、Q、PF、 Frequency, total active power, total reactive power, rate based power |

|

Equipment parameter query |

Address, range, transformation ratio, CT direction, voltage exceeding limit, frequency exceeding limit |

||

Switching input |

3-channel live line detection, 4-channel dry node detection |

||

Alarm limit exceeded |

9 alarm displays |

||

Electric meter calibration |

Pulse calibration table selection |

||

Equipment parameter settings |

Selection of settings for 10 functional categories |

||

RELAY CONTROL |

Automatic/manual selection and control of one set of relays |

||

Equipment information |

Version information of the instrument |

||

environment |

work environment |

Working temperature:- 20~60℃ |

|

storage environment |

Storage temperature:- 40~85℃ |

||

relative humidity |

Relative humidity ≤ 90%, no condensation |

||

electromagnetic compatibility |

pressure resistance |

4 kV |

|

surge |

Power supply 4 kV; I/O line 2kV |

||

BURST |

Power supply 4 kV; I/O line 2kV |

||

Electrostatic Discharge |

Air discharge 15 kV |

||

4. Installation and wiring

4.1 External structural dimensions:

Host size: 96 mm × 96 mm × 62.5mm

Hole size: 90mm × 90mm

Display type: LCD

Figure 4.1 Dimensions of NA-M70S4 Three phase Electronic Multi circuit Smart Meter

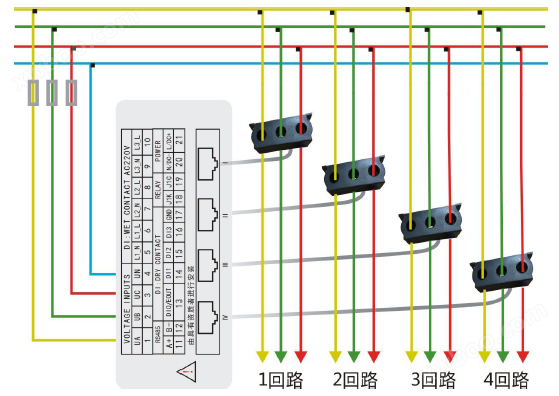

4.2 Wiring diagram

Figure 4.2 Wiring diagram of NA-M70S4 three-phase electronic multi circuit smart meter

4.3 Wiring Terminal Diagram

Figure 4.3 NA-M70S4 Three phase Electronic Multi circuit Smart Meter Wiring Terminal Diagram

4.4 Terminal Definition

Table 4.1 Definition of Instrument Terminals

terminal number |

Name |

Definition |

1 |

Ua |

A-phase voltage input terminal |

2 |

Ub |

B-phase voltage input terminal |

3 |

Uc |

C-phase voltage input terminal |

4 |

Un |

Voltage common input terminal |

5 |

L1_N |

The first AC220 wet node input detects the status of the mains power supply. |

6 |

L1_L |

|

7 |

L2_N |

The second AC220 wet node input is used to detect the power status of the oil engine. |

8 |

L2_L |

|

9 |

L3_N |

The third AC220 wet node input defaults to detecting the lightning protection air switch status. |

10 |

L3_L |

|

11 |

A+ |

Positive pole of external RS-485 interface signal of the instrument |

12 |

B- |

Instrument external RS-485 interface signal negative pole |

13 |

DIN_0/EOUT |

This terminal is a multifunctional port that can be reused with DIN-0 channel. It is set through the LCD panel and can be used for power pulse, second pulse output, and lightning protection air switch status; Default is switch quantity (dry node) detection; |

14 |

DI1 |

The first dry node detects the status of the mains switch. Normal closure; Failed to disconnect. |

15 |

DI2 |

At the first dry node, check the status of the oil engine switch. Normal closure; Failed to disconnect. |

16 |

DI3 |

The first dry node is used to detect the status of lightning protection SPD. Normal closure; Failed to disconnect. |

17 |

GND |

Dry node switch input common ground. |

18 |

J1K |

Relay 1 normally open contact |

19 |

J1C |

Relay 1 common contact |

20 |

L/DC- |

Equipment power supply L/DC- |

21 |

N/DC+ |

Equipment power supply N/DC+ |

Ⅰ |

Ⅰ |

Current input terminal of the first circuit |

Ⅱ |

Ⅱ |

Current input terminal of the second circuit |

Ⅲ |

Ⅲ |

Current input terminal of the third circuit |

Ⅳ |

Ⅳ |

4th circuit current input terminal |

5. Key operation and display

In this chapter, you will learn about the detailed content of human-machine interaction in smart meters, including how to use operation buttons and access the required electrical parameter information; How to correctly set relevant parameters. The default password for the settings interface is 1234. The password can only be changed in the settings interface. If you forget the password, please consult the manufacturer's technical support.

5.1 Display Interface

The display screen is mainly composed of a 160 * 160 dot matrix LCD screen and buttons, and the display adopts a multi-level tree like Chinese menu mode.

Table 5.1 Key Query Interface

Level 1 interface |

Level 2 interface |

Level 3 interface |

Level 4 interface |

basic parameters |

Electrical parameters of the first circuit |

Phase voltage of the first circuit |

not have |

Voltage of the first route | |||

Phase current of the first circuit | |||

Active power of the first circuit | |||

Reactive power of the first circuit | |||

Power factor of the first circuit | |||

Frequency of the first loop | |||

Total energy consumption of the first circuit | |||

The first circuit rate 1 consumes electrical energy | |||

The first circuit rate 2 consumes electricity | |||

The rate of the first circuit is 3, which consumes electricity | |||

Electrical parameters of circuits 2/3/4 |

The first circuit rate 4 consumes electricity |

||

parameter query |

Basic parameters |

Address, baud rate, display and backlight time |

not have |

current range |

1-4 circuit current range |

||

current transformation ratio |

1-4 circuit current transformation ratio |

||

Voltage conversion ratio |

Voltage conversion ratio |

||

CT direction |

1-4 circuit CT direction |

||

Rate Period |

Number of time periods, time and rates for each period, 99 represents inactive |

||

Out of limit parameters |

Voltage exceeding the limit and frequency exceeding the limit |

||

Freeze interval |

Freeze for an entire quarter of an hour, freeze daily, and read monthly meters |

||

Switching input |

Switch input information |

|

|

Alarm limit exceeded |

City power outage, oil engine power supply, phase sequence error, voltage exceeding limit, frequency exceeding limit, lightning arrester failure, lightning arrester air disconnection, smart meter failure |

|

|

School schedule setting |

School schedule setting information |

not have |

|

Parameter setting |

Enter password 1234 |

basic parameters |

Parameter setting interface |

current range | |||

Level 1 interface |

Level 2 interface |

Level 3 interface |

Level 4 interface |

Parameter setting |

Enter password 1234 |

current transformation ratio |

Parameter setting interface |

Voltage conversion ratio | |||

CT direction | |||

Time slot rate | |||

Out of limit parameters | |||

Freeze interval | |||

Password Setting | |||

Time setting | |||

Selection of lightning protection air switch detection nodes | |||

relay status |

Relay status and control |

not have |

|

Equipment information |

Equipment information |

not have |

|

5.2 Buttons and Display

Figure 5.1 shows the content displayed in the root directory.

Figure 5.1 Root directory display

There are five nimble operation buttons on the front panel, labeled from left to right as the "ESC" key, "▲" key, "▼" key, "►" key, and "ENT" key, which respectively realize the functions of canceling, adding or moving up, subtracting or moving down, flipping pages or moving right, and confirming. The display of different measurement data and parameter settings can be achieved through the operation of five buttons.

5.3 Operation of displaying measurement data

Press the "▲" and "▼" keys on the screen in Figure 5.1 to move the cursor up and down in a loop. When the cursor is at the "Basic Parameters" position, press the "ENT" key to enter the circuit selection interface, as shown in Figure 5.2.

Figure 5.2 Electrical Parameter Circuit Selection Interface

Press the "▲" and "▼" keys to cycle the cursor up and down, select the circuit that needs to display electrical parameters, and press the "ENT" key to enter the basic parameter display page. Press the "►" and "▼" keys to scroll down the screen, and press the "▲" key to scroll up the screen. Each press will flip one screen. Pressing the 'ESC key' on any displayed screen will return to the previous layer, which is the screen shown in Figure 5.1.

6. Function demonstration

6.1 Telemetry Data

The instrument itself has a 4-circuit three-phase detection, and an external three-phase integrated transformer is selected by default. The current CT is connected through a crystal head. Having all the telemetry information required by the standard, and having functions such as phase separated energy statistics.

Figure 6.1 Electrical parameter acquisition interface

6.2 Remote signaling

The NA-M70S4 has 7 DI input detections: L1-N and L1_L, L2-N and L2_L, L3-N and L3_L are 3 AC220V live wire detection inputs, DI0, DI1, DI2, DI3 are 4 dry contact inputs, and GND is the common terminal. Among them, L1-N and L1_L are for mains power supply detection, L2-N and L2_L are for oil engine power supply detection, and L3-N and L3_L are default for lightning protection circuit breaker detection. The lightning protection circuit breaker detection can be set to select "3rd live wire detection/0th dry node" in the panel "6. Parameter settings" → "6-11 lightning protection circuit breaker selection". DI0 is a dry node that is multiplexed with a multifunctional pulse interface. When selecting DI0 dry node as the input terminal for lightning protection air switches, please confirm the "current pulse output: no output" mode in "5. Calibration settings". For detailed wiring information, please refer to 4.4 Terminal Definition. Dry node DI1 is for detecting mains power switches, dry node DI2 is for detecting oil engine power supply, and dry node DI3 is for detecting lightning arrester faults.

Figure 6.2 Interface for obtaining switch status

6.3 Reading Historical Data

Historical data is divided into interval data of 15 minutes, daily zero hour historical data, and monthly meter reading day historical data.

Figure 6.3 Reading Historical Data Interface

6.4 School Table Setting

The NA-M70S4 smart meter has a multifunctional pulse output interface EOUT, which is multiplexed with the DI0 interface. Before calibrating the meter, it needs to be set to pulse output through the panel, and there is no pulse output by default.

For example, detecting the active pulse output of the first circuit:

Select "5. Calibration Table Setting" in the root directory of Figure 5.1 and press the "ENT" key to enter the calibration table setting interface. Press the "▲" or "▼" keys to set the selected pulse output to "Select Pulse Output: First Active Output". After successfully setting with the "ENT" key, the current pulse output will display "Current Pulse Output: First Active Output", and the EOUT interface will output the first active pulse.

Pulse output options include: first active output, first reactive output, second active output, second reactive output, third active output, third reactive output, fourth active output, fourth reactive output, second pulse output, and reactive output. The setting method is the same as the first pulse output method.

7. Packaging

When opening the product packaging, please carefully check for any damage. If there is any damage, please contact the manufacturer in a timely manner and keep the damaged packaging. Our company will handle it promptly.

8. Precautions

8.1. Usage and Storage Conditions

Please use under normal temperature, atmospheric pressure, dust-free, and dry conditions.

8.2 Load Capacity

Do not use under overload.

9. Service and Warranty (provided by the market)

10 Simple Fault Analysis and Troubleshooting

10.1. LCD does not light up

LCD not lit: Please check the power supply to ensure it is powered on.

10.2. Abnormal Unit Communication

Check the wiring of RS485 to ensure that wires A and B are not reversed. If you are using another company's RS485 to RS232 connection unit, please ensure its communication stability and reliability.

Ordering Example:

model: NA-M70S4

Application scenario: Three phase four wire system

Voltage connection: directly connected to AC220V

Current access: 100A/100mA, 60A/60mA.