VIP member

Transformer oil vacuum oil filter

Product Name: Transformer Oil Vacuum Filter Product Number: QJA-S Series Main Material: High carbon steel, customizable stainless steel Working Princi

Product details

Product Name: QJA-S Series Transformer Oil Vacuum FilterAdvantages of Dingneng oil filter

Product Overview:

This series of models is a specialized equipment developed specifically for oil filtration and vacuum extraction requirements of 220/500/750KV and above power transmission and transformation equipment.

Mainly used for purifying insulating oil, removing its moisture, gas, and mechanical impurities, thereby improving the withstand voltage strength and oil quality of insulating oil, ensuring the safe operation of high-voltage electrical equipment. The processed oil meets the national standard for use and is a commonly used oil filtration equipment in the power industry.

Product Usage:

Used for the construction, installation, maintenance, and on-site inspection of ultra-high voltage transmission and transformation equipment.

Used for deep purification treatment of oil products such as capacitors, transformers, and ultra-high voltage transformers.

● It has the function of refueling and replenishing oil for transformers.

Used for circulating drying treatment of transformers.

It can achieve transformer vacuum pumping and vacuum oil injection at the same time.

Adopting a dual stage high vacuum design, this series of models has more advantages when used in high-altitude areas.

Product advantages:

High efficiency in water and gas removal: Adopting Dingneng's patented three-dimensional evaporation and dehydration system, a unique stainless steel folding cyclone separation tower, and increasing the separation area to make the oil thin film. Built in secondary evaporation layer, combined with special vacuum packing, increases the contact area of the oil film, quickly separates water and gas in the oil, and has very high efficiency. (Patent number: 2014202545183)

Strong impurity removal ability: High beta value precision filter material, multi-stage filtration with step-by-step encryption, removes fine particles from the oil. The filter element has a large volume and a large dirt holding capacity. Long service life and equipped with automatic detection function for filter contamination.

Short oil processing time: Double stage high vacuum and high pumping speed can quickly and efficiently remove water vapor from the oil, improve the dryness and breakdown voltage of the oil, and greatly improve the filtration effect in one filtration, shorten the oil processing period, and thus improve the performance of the oil.

● Uniform heating: The system adopts low-density indirect circulation carbon fiber heating technology to prevent the cracking of oil and the production of acetylene gas. Low energy consumption, uniform heating, and stable oil temperature.

● Automation control: This machine adopts high-end and sophisticated configurations such as automatic constant temperature control, photoelectric liquid level control, automatic defoaming control, and automatic pressure protection to ensure that the equipment does not spray oil during operation and operates safely and stably.

Interlocking protection: overload protection, overpressure alarm shutdown protection, fuel shortage protection, fuel injection protection, phase sequence protection, etc. ensure the long-term reliable operation of the whole machine.

● Humanized indication: Automated design with clear and concise indications for oil temperature, pressure, vacuum level, filter contamination level, and operating status.

Modern design: The oil purification process of this machine is designed with advanced technology, which can be processed online or offline. It has a high degree of automation and can achieve unmanned operation. The device has a compact structure and is flexible and convenient to move.

● Good comprehensive performance: This machine has the advantages of low noise, easy operation, long maintenance intervals, low energy consumption, low operating costs, and high oil filtration efficiency.

Optional devices:

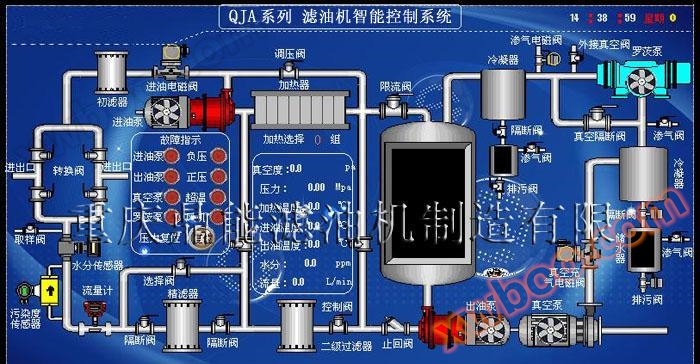

A can be equipped with an optional PLC (Intelligent Programmable Logic Control System): a touch screen human-machine dialogue operation interface with dynamic display. (Optional)

B Imported components (such as imported brand vacuum pump sets, motor oil pump sets, filter elements, electrical components, instruments, etc.).(Optional)

C flowmeter. (Optional)

The D configuration frequency conversion system can achieve flow selection during oil filtration or injection. (Optional)

E online micro water meter. (Optional)

F vacuum gauge. (Optional)

Intelligent control system:

Optional exterior structure:

Base structure: 1. Mobile roller type; 2. Fixed installation type; 3. Mobile trailer type;

Rack structure: A. Open type; B、 Ceiling canopy type; C、 Fully enclosed rainproof house; D、 Canvas canopy shelter type;

Material selection: 1. High carbon steel; 2. Oil circuit stainless steel; 3. All stainless steel.

Color selection: Milk white; Blue sky; Grassland green; Industrial ash; Warning yellow.

Online inquiry