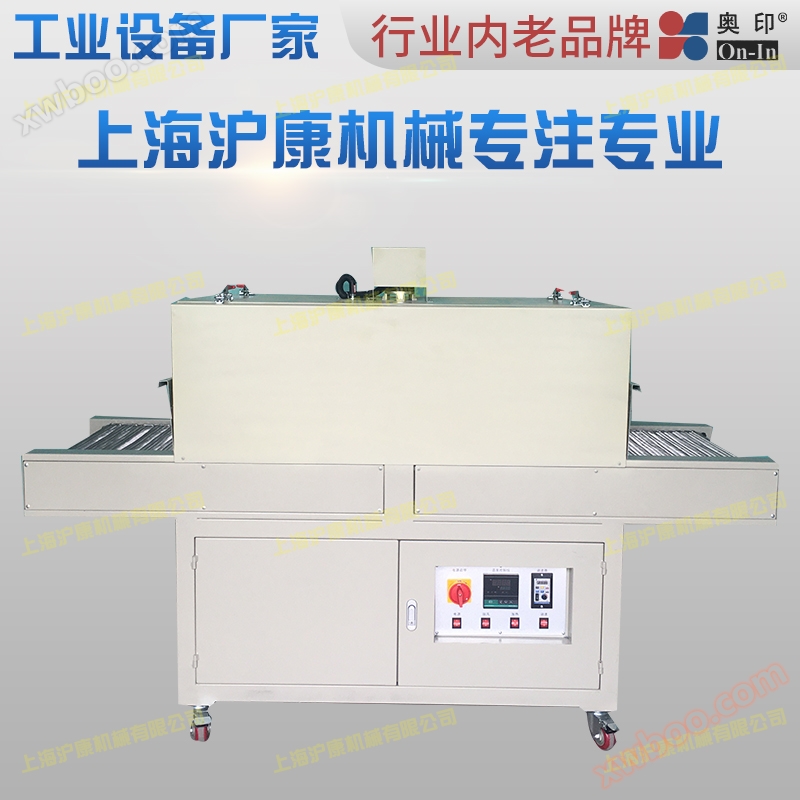

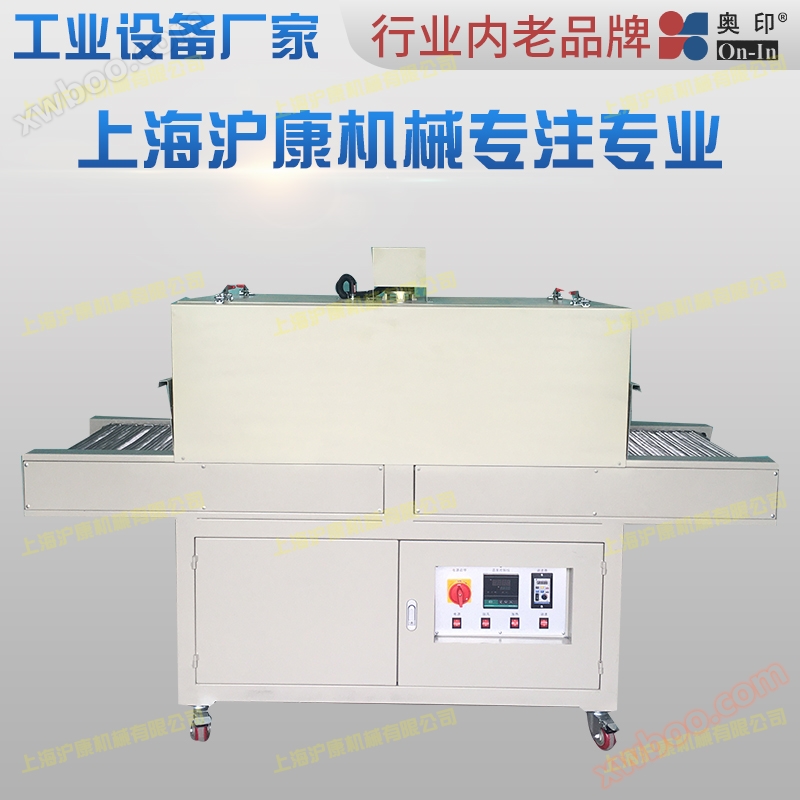

Tunnel oven 2000

This oven is a hot air circulation tunnel oven that adopts the newly promoted far-infrared heating technology in the market. After being heated, far-infrared components can uniformly emit far-infrared radiation of 2-15 microns or more. When it is absorbed by the heated object, it can be directly converted into heat energy, achieving the effect of accelerating drying from the surface, shortening production cycles, saving energy, and improving product quality. Easy to use, with obvious effects. This oven is made of angle steel, thin steel plate, and stainless steel plate. Aluminum silicate fiber insulation is filled between the outer shell and the working chamber. The far-infrared heater is installed in the working chamber air duct. The air inside the box is enclosed and self circulating. The studio and conveyor belt are made of 304 stainless steel structure. The temperature inside the studio is automatically controlled by a temperature controller, and there are automatic constant temperature and time control devices. They are also equipped with automatic power-off and alarm circuits for overheating. The quality is reliable and the use is safe. thispipelineOven is suitable for purifying and drying requirements in workshops or laboratories of the printed circuit board industry, electronic products, medical supplies, colleges and research departments

rule grid

1. Power supply AC220V, 2 Φ, 50HZ, heating power:3KW, Blast power 220V/40W * 1 unit

2. Working size: Long2000MMX width610MMX high1350MM

3.Heating size: long1200MMX width475MMX high100MM

4. Temperature range: room temperature~ 100 ℃,

Our company can customize according to needs