Model Meaning

Product Introduction

Water is the source of human life, and human survival cannot be without water for a day.

With the continuous improvement of urbanization level in our country, the urban population has increased sharply, and the continuous expansion and renovation of urban residential buildings have led to the continuous increase of residential floors and the expansion of urban areas. The pressure on the original municipal pipeline network is becoming increasingly insufficient, and in most areas, there is a widespread problem of low water supply pressure during peak periods, making it difficult for high-rise users to use water. So most buildings add secondary pressurization equipment, build reservoirs and high-level water tanks, which can supply water through water pumps for secondary pressurization. However, this traditional secondary pressurization equipment has many disadvantages such as high investment and easy secondary pollution of water sources.

The WB type non negative pressure water supply equipment developed and produced by our company can be connected in series to the urban government pipe network for secondary pressurization of users. This water supply equipment does not require the construction of reservoirs or high-level water tanks, and can be directly connected in series to the municipal pipe network. When the equipment operates normally, it will not create negative pressure (suction) on the municipal pipe network, fully complying with the requirements of China's "Urban Water Supply Regulations". It can fully utilize the original pressure of the municipal pipe network and adopt variable frequency speed regulation for water supply, which has a significant energy-saving effect. After being introduced to the market, it has been highly favored by Fangda users.

Equipment features

1. No need to set up reservoirs and high-level water tanks

The complete set of equipment for non negative pressure water supply is directly connected to the municipal pipeline network, without the need to build reservoirs and high-level water tanks, saving engineering investment and reducing the occupation of building area.

When the municipal water supply network has sufficient water supply, the volume of the non negative pressure steady flow tank is small, and the entire equipment occupies a small area. The installation of the equipment only requires connecting the inlet and outlet water pipes, which is extremely convenient.

2. Secondary pollution without water source

The non negative pressure steady flow tank and the entire equipment pipeline are all sealed, from the municipal pipeline network to the user's faucet, they will not be subject to secondary pollution from debris and dirt in the air. The overflow part of the non negative pressure steady flow source tank is treated with anti-corrosion coating on the inner wall of the food container, and the coating and non negative pressure water supply equipment meet relevant food hygiene standards.

3. Significant energy-saving effect

The traditional secondary pressurized water supply method uses a reservoir and a high-level water tank. When the municipal pipe network water supply pressure is put into the reservoir, the energy loss is exhausted and the energy waste is serious.

After adopting a non negative pressure steady flow tank, the water supply pressure of the municipal pipeline network is directly superimposed on the inlet of the water supply pump, and the pump only needs to supplement the insufficient pressure of the municipal pipeline network, resulting in significant energy-saving effect of the whole machine.

4. No need to set up a stabilizing pump and a large volume pressure tank

In order to prevent frequent start-up of the water supply pump in case of small or zero flow leakage into the pipeline network at night, the general water supply equipment is equipped with a low flow stabilizing pump and a large volume SQL diaphragm pressure tank. This not only increases the one-time investment of the water supply equipment, but also increases the operating cost of the equipment (the power consumption of the stabilizing pump during nighttime operation).

During the low peak period of water use in the evening, the water supply pressure and volume of the municipal water supply network can basically meet the requirements of users. After adopting the WB type non negative pressure water supply equipment, the original pressure of the municipal water supply network is fully utilized, and the water in the municipal water supply network is directly supplied to users. The WB type non negative pressure water supply equipment does not require equipment stabilizing pumps and large volume SQL diaphragm pressure tanks, which saves investment and significantly improves the energy-saving effect of the WB type non negative pressure water supply equipment during operation.

work environment

1. Power supply voltage fluctuation ≤ ± 10%;

2. Surrounding environmental temperature: -10 ℃ -+40 ℃ (not frozen);

3. Relative humidity of the air: 20% -90% (no condensation);

4. Altitude: ≤ 1000m;

5. Places without conductive dust that can corrode metals and damage insulation gases in Egypt;

6. Places without explosion hazards;

7. Vibration:<5.9m/s2 (0.6G), inclination: ≤ 5 degrees in places;

8. Places with rain and earthquake resistant equipment and no water vapor;

Working principle

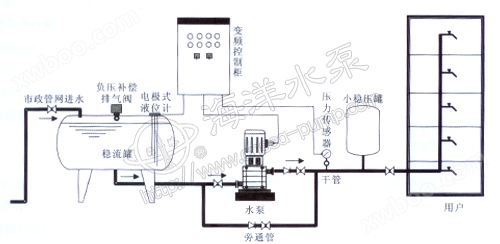

When the WB type non negative pressure water supply equipment is put into normal use, water from the municipal pipeline enters the non negative pressure steady flow tank, and a large amount of air inside the tank is discharged from the exhaust valve. When the air is exhausted, the floating ball inside the valve is lifted by removing water, and the transmission plug is moved to the closed position. Slowly close the exhaust port, stop the exhaust, and prevent water from flowing out. When the water flow in the steady flow tank is normal, if a small amount of air accumulates in the valve to a considerable extent, the water level inside the valve will drop, and the floating ball will follow suit. At this time, the air will be discharged through the exhaust hole.

During the normal operation of the WB type non negative pressure water supply equipment, when the municipal water supply network is insufficient, the water flow in the municipal inlet pipe is empty, or the water pressure in the stabilizing tank is lower than atmospheric pressure, the water level in the stabilizing tank drops, and the floating ball descends accordingly, driving the plug to open and suck in air, so as to maintain atmospheric pressure in the stabilizing tank and prevent negative pressure on the municipal water supply network.

When the pressure in the municipal pipeline network is lower than the set pressure required by the user, the water pump operates with variable frequency speed regulation to ensure that the pressure in the user's pipeline network meets the user's water requirements. The higher the water pressure in the municipal pipeline network. The lower the speed of the water pump, the lower the water pressure in the municipal pipeline network, and the higher the speed of the water pump. When the water supply pressure of the municipal pipeline network reaches the user's requirements, the WB type non negative pressure water supply equipment will automatically stop working, and the water in the municipal pipeline network will be directly supplied to the user through the bypass pipe.

When the municipal pipeline network stops supplying water, the water level in the stabilizing tank gradually decreases. When it drops to a low water level, the liquid level gauge on the stabilizing tank sends a shutdown signal, and the WB type non negative pressure water supply equipment automatically stops running and displays a water shortage protection signal.

When the power grid is cut off, the WB type non negative pressure water supply equipment will shut down, and the water in the municipal pipeline network will be directly supplied to users through the bypass pipe of the WB type non negative pressure water supply equipment.

|

Technical Parameter

Serial Number |

Equipment model |

internet traffic |

lift |

Pump model |

power |

Stable flow tank |

Equipped with control cabinet |

|

m3/h |

m |

kW |

Specification (Dg-L) |

volume |

||||

1 |

WBOC2/2-0.30 |

4 |

30 |

CDL2-40 |

0.55 |

WLG600-1000 |

0.25 |

HYB-0.55-2 |

2 |

WBOC2/2-0.37 |

4 |

37 |

CDL2-50 |

0.55 |

WLG600-1000 |

0.25 |

HYB-0.55-2 |

3 |

WBOC2/2-0.45 |

4 |

45 |

CDL2-60 |

0.75 |

WLG600-1000 |

0.25 |

HYB-0.75-2 |

4 |

WBOC2/2-0.52 |

4 |

52 |

CDL2-70 |

0.75 |

WLG600-1000 |

0.25 |

HYB-0.75-2 |

5 |

WBOC2/2-0.67 |

4 |

67 |

CDL2-90 |

1.1 |

WLG600-1000 |

0.25 |

HYB-1.1-2 |

6 |

WBOC2/2-0.82 |

4 |

82 |

CDL2-110 |

1.1 |

WLG600-1000 |

0.25 |

HYB-1.1-2 |

7 |

WBOC2/2-1.12 |

4 |

112 |

CDL2-150 |

1.5 |

WLG600-1000 |

0.25 |

HYB-1.5-2 |

8 |

WBOC2/2-1.35 |

4 |

135 |

CDL2-180 |

2.2 |

WLG600-1000 |

0.25 |

HYB-2.2-2 |

9 |

WBOC4/2-0.32 |

8 |

32 |

CDL4-40 |

0.75 |

WLG600-1000 |

0.25 |

HYB-0.75-2 |

10 |

WBOC4/2-0.40 |

8 |

40 |

CDL4-50 |

1.1 |

WLG600-1000 |

0.25 |

HYB-1.1-2 |

11 |

WBOC4/2-0.48 |

8 |

48 |

CDL4-60 |

1.1 |

WLG600-1000 |

0.25 |

HYB-1.1-2 |

12 |

WBOC4/2-0.64 |

8 |

64 |

CDL4-80 |

1.5 |

WLG600-1000 |

0.25 |

HYB-1.5-2 |

13 |

WBOC4/2-0.80 |

8 |

80 |

CDL4-100 |

2.2 |

WLG600-1000 |

0.25 |

HYB-2.2-2 |

14 |

WBOC4/2-0.96 |

8 |

96 |

CDL4-120 |

2.2 |

WLG600-1000 |

0.25 |

HYB-2.2-2 |

15 |

WBOC4/2-1.28 |

8 |

128 |

CDL4-160 |

3 |

WLG600-1000 |

0.25 |

HYB-3-2 |

16 |

WBOC4/2-1.52 |

8 |

152 |

CDL4-190 |

4 |

WLG600-1000 |

0.25 |

HYB-4-2 |

17 |

WBOC8/2-0.36 |

16 |

36 |

CDL8-40 |

1.5 |

WLG800-1300 |

0.58 |

HYB-1.5-2 |

18 |

WBOC8/2-0.45 |

16 |

45 |

CDL8-50 |

2.2 |

WLG800-1300 |

0.58 |

HYB-2.2-2 |

19 |

WBOC8/2-0.54 |

16 |

54 |

CDL8-60 |

2.2 |

WLG800-1300 |

0.58 |

HYB-2.2-2 |

20 |

WBOC8/2-0.72 |

16 |

72 |

CDL8-80 |

3 |

WLG800-1300 |

0.58 |

HYB-3-2 |

21 |

WBOC8/2-0.90 |

16 |

90 |

CDL8-100 |

4 |

WLG800-1300 |

0.58 |

HYB-4-2 |

22 |

WBOC8/2-1.08 |

16 |

108 |

CDL8-120 |

4 |

WLG800-1300 |

0.58 |

HYB-4-2 |

23 |

WBOC8/2-1.26 |

16 |

126 |

CDL8-140 |

5.5 |

WLG800-1300 |

0.58 |

HYB-5.5-2 |

24 |

WBOC8/2-1.44 |

16 |

144 |

CDL8-160 |

5.5 |

WLG800-1300 |

0.58 |

HYB-5.5-2 |

25 |

WBOC16/2-0.36 |

32 |

36 |

CDL16-30 |

3 |

WLG1000-1600 |

1.1 |

HYB-3-2 |

26 |

WBOC16/2-0.48 |

32 |

48 |

CDL16-40 |

4 |

WLG1000-1600 |

1.1 |

HYB-4-2 |

27 |

WBOC16/2-0.60 |

32 |

60 |

CDL16-50 |

5.5 |

WLG1000-1600 |

1.1 |

HYB-5.5-2 |

28 |

WBOC16/2-0.72 |

32 |

72 |

CDL16-60 |

5.5 |

WLG1000-1600 |

1.1 |

HYB-5.5-2 |

29 |

WBOC16/2-0.84 |

32 |

84 |

CDL16-70 |

7.5 |

WLG1000-1600 |

1.1 |

HYB-7.5-2 |

30 |

WBOC16/2-0.96 |

32 |

96 |

CDL16-80 |

7.5 |

WLG1000-1600 |

1.1 |

HYB-7.5-2 |

31 |

WBOC16/2-1.20 |

32 |

120 |

CDL16-100 |

11 |

WLG1000-1600 |

1.1 |

HYB-11-2 |

32 |

WBOC16/2-1.44 |

32 |

144 |

CDL16-120 |

11 |

WLG1000-1600 |

1.1 |

HYB-11-2 |

Serial Number |

Equipment model

|

internet traffic |

lift |

Pump model

|

power |

Stable flow tank |

Equipped with control cabinet

|

|

m3/h |

m |

kW |

Specification (Dg-L) |

volume |

||||

33 |

WBOG2/3-0.36 |

6 |

36 |

25GDL2-12×3 |

1.1 |

WLG600-1000 |

0.25 |

HYB-1.1-3V |

34 |

WBOG2/3-0.48 |

6 |

48 |

25GDL2-12×4 |

1.1 |

WLG600-1000 |

0.25 |

HYB-1.1-3V |

35 |

WBOG2/3-0.60 |

6 |

60 |

25GDL2-12×5 |

1.5 |

WLG600-1000 |

0.25 |

HYB-1.5-3V |

36 |

WBOG2/3-0.72 |

6 |

72 |

25GDL2-12×6 |

1.5 |

WLG600-1000 |

0.25 |

HYB-1.5-3V |

37 |

WBOG2/3-0.84 |

6 |

84 |

25GDL2-12×7 |

2.2 |

WLG600-1000 |

0.25 |

HYB-2.2-3V |

38 |

WBOG2/3-0.96 |

6 |

96 |

25GDL2-12×8 |

2.2 |

WLG600-1000 |

0.25 |

HYB-2.2-3V |

39 |

WBOG2/3-1.08 |

6 |

108 |

25GDL2-12×9 |

2.2 |

WLG600-1000 |

0.25 |

HYB-2.2-3V |

40 |

WBOG2/3-1.20 |

6 |

120 |

25GDL2-12×10 |

3 |

WLG600-1000 |

0.25 |

HYB-3-3V |

41 |

WBOG2/3-1.32 |

6 |

132 |

25GDL2-12×11 |

3 |

WLG600-1000 |

0.25 |

HYB-3-3V |

42 |

WBOG2/3-1.44 |

6 |

144 |

25GDL2-12×12 |

3 |

WLG600-1000 |

0.25 |

HYB-3-3V |

43 |

WBOG2/3-1.56 |

6 |

156 |

25GDL2-12×13 |

4 |

WLG600-1000 |

0.25 |

HYB-4-3V |

44 |

WBOG2/3-1.68 |

6 |

168 |

25GDL2-12×14 |

4 |

WLG600-1000 |

0.25 |

HYB-4-3V |

45 |

WBOG2/3-1.80 |

6 |

180 |

25GDL2-12×15 |

4 |

WLG600-1000 |

0.25 |

HYB-4-3V |

46 |

WBOG4/3-0.33 |

12 |

33 |

25GDL4-11×3 |

1.1 |

WLG600-1000 |

0.25 |

HYB-1.1-3V |

47 |

WBOG4/3-0.44 |

12 |

44 |

25GDL4-11×4 |

1.5 |

WLG600-1000 |

0.25 |

HYB-1.5-3V |

48 |

WBOG4/3-0.55 |

12 |

55 |

25GDL4-11×5 |

2.2 |

WLG600-1000 |

0.25 |

HYB-2.2-3V |

49 |

WBOG4/3-0.66 |

12 |

66 |

25GDL4-11×6 |

2.2 |

WLG600-1000 |

0.25 |

HYB-2.2-3V |

50 |

WBOG4/3-0.77 |

12 |

77 |

25GDL4-11×7 |

3 |

WLG600-1000 |

0.25 |

HYB-3-3V |

51 |

WBOG4/3-0.88 |

12 |

88 |

25GDL4-11×8 |

3 |

WLG600-1000 |

0.25 |

HYB-3-3V |

52 |

WBOG4/3-0.99 |

12 |

99 |

25GDL4-11×9 |

3 |

WLG600-1000 |

0.25 |

HYB-4-3V |

53 |

WBOG4/3-1.10 |

12 |

110 |

25GDL4-11×10 |

4 |

WLG600-1000 |

0.25 |

HYB-4-3V |

54 |

WBOG4/3-1.21 |

12 |

121 |

25GDL4-11×11 |

4 |

WLG600-1000 |

0.25 |

HYB-4-3V |

55 |

WBOG4/3-1.32 |

12 |

132 |

25GDL4-11×12 |

4 |

WLG600-1000 |

0.25 |

HYB-4-3V |

56 |

WBOG4/3-1.43 |

12 |

143 |

25GDL4-11×13 |

4 |

WLG600-1000 |

0.25 |

HYB-4-3V |

57 |

WBOG4/3-1.54 |

12 |

154 |

25GDL4-11×14 |

5.5 |

WLG600-1000 |

0.25 |

HYB-5.5-3V |

58 |

WBOG4/3-1.65 |

12 |

165 |

25GDL4-11×15 |

5.5 |

WLG600-1000 |

0.25 |

HYB-5.5-3Vn |

Serial Number |

Equipment model

|

internet traffic |

lift |

Pump model

|

power |

Stable flow tank |

Equipped with control cabinet

|

|

m3/h |

m |

kW |

Specification (Dg-L) |

volume |

||||

59 |

WBOG6/3-0.36 |

18 |

36 |

40GDL6-12×3 |

1.5 |

WLG800-1300 |

0.58 |

HYB-1.5-3V |

60 |

WBOG6/3-0.48 |

18 |

48 |

40GDL6-12×4 |

2.2 |

WLG800-1300 |

0.58 |

HYB-2.2-3V |

61 |

WBOG6/3-0.60 |

18 |

60 |

40GDL6-12×5 |

2.2 |

WLG800-1300 |

0.58 |

HYB-2.2-3V |

62 |

WBOG6/3-0.72 |

18 |

72 |

40GDL6-12×6 |

3 |

WLG800-1300 |

0.58 |

HYB-3-3V |

63 |

WBOG6/3-0.84 |

18 |

84 |

40GDL6-12×7 |

3 |

WLG800-1300 |

0.58 |

HYB-3-3V |

64 |

WBOG6/3-0.96 |

18 |

96 |

40GDL6-12×8 |

4 |

WLG800-1300 |

0.58 |

HYB-4-3V |

65 |

WBOG6/3-1.08 |

18 |

108 |

40GDL6-12×9 |

4 |

WLG800-1300 |

0.58 |

HYB-4-3V |

66 |

WBOG6/3-1.20 |

18 |

120 |

40GDL6-12×10 |

4 |

WLG800-1300 |

0.58 |

HYB-4-3V |

67 |

WBOG6/3-1.32 |

18 |

132 |

40GDL6-12×11 |

5.5 |

WLG800-1300 |

0.58 |

HYB-5.5-3V |

68 |

WBOG6/3-1.44 |

18 |

144 |

40GDL6-12×12 |

5.5 |

WLG800-1300 |

0.58 |

HYB-5.5-3V |

69 |

WBOG6/3-1.56 |

18 |

156 |

40GDL6-12×13 |

7.5 |

WLG800-1300 |

0.58 |

HYB-7.5-3V |

70 |

WBOG6/3-1.68 |

18 |

168 |

40GDL6-12×14 |

7.5 |

WLG800-1300 |

0.58 |

HYB-7.5-3V |

71 |

WBOG6/3-1.80 |

18 |

180 |

40GDL6-12×15 |

7.5 |

WLG800-1300 |

0.58 |

HYB-7.5-3V |

72 |

WBOG12/3-0.30 |

36 |

30 |

50GDL12-15×2 |

2.2 |

WLG1000-1600 |

1.1 |

HYB-2.2-3V |

73 |

WBOG12/3-0.45 |

36 |

45 |

50GDL12-15×3 |

3 |

WLG1000-1600 |

1.1 |

HYB-3-3V |

74 |

WBOG12/3-0.60 |

36 |

60 |

50GDL12-15×4 |

4 |

WLG1000-1600 |

1.1 |

HYB-4-3V |

75 |

WBOG12/3-0.75 |

36 |

75 |

50GDL12-15×5 |

5.5 |

WLG1000-1600 |

1.1 |

HYB-5.5-3V |

76 |

WBOG12/3-0.90 |

36 |

90 |

50GDL12-15×6 |

5.5 |

WLG1000-1600 |

1.1 |

HYB-5.5-3V |

77 |

WBOG12/3-1.05 |

36 |

105 |

50GDL12-15×7 |

7.5 |

WLG1000-1600 |

1.1 |

HYB-7.5-3V |

78 |

WBOG12/3-1.20 |

36 |

120 |

50GDL12-15×8 |

7.5 |

WLG1000-1600 |

1.1 |

HYB-7.5-3V |

79 |

WBOG12/3-1.35 |

36 |

135 |

50GDL12-15×9 |

11 |

WLG1000-1600 |

1.1 |

HYB-11-3V |

80 |

WBOG12/3-1.50 |

36 |

150 |

50GDL12-15×10 |

11 |

WLG1000-1600 |

1.1 |

HYB-11-3V |

Serial Number |

Equipment model

|

internet traffic |

lift |

Pump model

|

power |

Stable flow tank |

Equipped with control cabinet

|

|

m3/h |

m |

kW |

Specification (Dg-L) |

volume |

||||

81 |

WBOG18/3-0.30 |

54 |

30 |

50GDL18-15×2 |

3 |

WLG1200-2000 |

2.0 |

HYB-3-3V |

82 |

WBOG18/3-0.45 |

54 |

45 |

50GDL18-15×3 |

4 |

WLG1200-2000 |

2.0 |

HYB-4-3V |

83 |

WBOG18/3-0.60 |

54 |

60 |

50GDL18-15×4 |

5.5 |

WLG1200-2000 |

2.0 |

HYB-5.5-3V |

84 |

WBOG18/3-0.75 |

54 |

75 |

50GDL18-15×5 |

7.5 |

WLG1200-2000 |

2.0 |

HYB-7.5-3V |

85 |

WBOG18/3-0.90 |

54 |

90 |

50GDL18-15×6 |

7.5 |

WLG1200-2000 |

2.0 |

HYB-7.5-3V |

86 |

WBOG18/3-1.05 |

54 |

105 |

50GDL18-15×7 |

11 |

WLG1200-2000 |

2.0 |

HYB-11-3V |

87 |

WBOG18/3-1.20 |

54 |

120 |

50GDL18-15×8 |

11 |

WLG1200-2000 |

2.0 |

HYB-11-3V |

88 |

WBOG18/3-1.35 |

54 |

135 |

50GDL18-15×9 |

15 |

WLG1200-2000 |

2.0 |

HYB-15-3V |

89 |

WBOG18/3-1.50 |

54 |

150 |

50GDL18-15×10 |

15 |

WLG1200-2000 |

2.0 |

HYB-15-3V |

90 |

WBOG24/3-0.24 |

72 |

24 |

65GDL24-12×2 |

3 |

WLG1200-2000 |

2.0 |

HYB-3-3V |

91 |

WBOG24/3-0.36 |

72 |

36 |

65GDL24-12×3 |

4 |

WLG1200-2000 |

2.0 |

HYB-4-3V |

92 |

WBOG24/3-0.48 |

72 |

48 |

65GDL24-12×4 |

5.5 |

WLG1200-2000 |

2.0 |

HYB-5.5-3V |

93 |

WBOG24/3-0.60 |

72 |

60 |

65GDL24-12×5 |

7.5 |

WLG1200-2000 |

2.0 |

HYB-7.5-3V |

94 |

WBOG24/3-0.72 |

72 |

72 |

65GDL24-12×6 |

7.5 |

WLG1200-2000 |

2.0 |

HYB-7.5-3V |

95 |

WBOG24/3-0.84 |

72 |

84 |

65GDL24-12×7 |

11 |

WLG1200-2000 |

2.0 |

HYB-11-3V |

96 |

WBOG24/3-0.96 |

72 |

96 |

65GDL24-12×8 |

11 |

WLG1200-2000 |

2.0 |

HYB-11-3V |

97 |

WBOG24/3-1.08 |

72 |

108 |

65GDL24-12×9 |

15 |

WLG1200-2000 |

2.0 |

HYB-15-3V |

98 |

WBOG24/3-1.20 |

72 |

120 |

65GDL24-12×10 |

15 |

WLG1200-2000 |

2.0 |

HYB-15-3V |

99 |

WBOG24/3-1.32 |

72 |

132 |

65GDL24-12×11 |

15 |

WLG1200-2000 |

2.0 |

HYB-15-3V |

100 |

WBOG24/3-1.44 |

72 |

144 |

65GDL24-12×12 |

18.5 |

WLG1200-2000 |

2.0 |

HYB-18.5-3V |

101 |

WBOG36/3-0.24 |

108 |

24 |

80GDL36-12×2 |

4 |

WLG1400-2500 |

3.5 |

HYB-4-3V |

102 |

WBOG36/3-0.36 |

108 |

36 |

80GDL36-12×3 |

5.5 |

WLG1400-2500 |

3.5 |

HYB-5.5-3V |

103 |

WBOG36/3-0.48 |

108 |

48 |

80GDL36-12×4 |

7.5 |

WLG1400-2500 |

3.5 |

HYB-7.5-3V |

104 |

WBOG36/3-0.60 |

108 |

60 |

80GDL36-12×5 |

11 |

WLG1400-2500 |

3.5 |

HYB-11-3V |

105 |

WBOG36/3-0.72 |

108 |

72 |

80GDL36-12×6 |

11 |

WLG1400-2500 |

3.5 |

HYB-11-3V |

106 |

WBOG36/3-0.84 |

108 |

84 |

80GDL36-12×7 |

15 |

WLG1400-2500 |

3.5 |

HYB-15-3V |

107 |

WBOG36/3-0.96 |

108 |

96 |

80GDL36-12×8 |

15 |

WLG1400-2500 |

3.5 |

HYB-15-3V |

108 |

WBOG36/3-1.08 |

108 |

108 |

80GDL36-12×9 |

18.5 |

WLG1400-2500 |

3.5 |

HYB-18.5-3V |

109 |

WBOG36/3-1.20 |

108 |

120 |

80GDL36-12×10 |

18.5 |

WLG1400-2500 |

3.5 |

HYB-18.5-3V |

Serial Number |

Equipment model

|

internet traffic |

lift |

Pump model

|

power |

Stable flow tank |

Equipped with control cabinet

|

|

m3/h |

m |

kW |

Specification (Dg-L) |

volume |

||||

110 |

WBOG54/3-0.28 |

162 |

28 |

80GDL54-14×2 |

7.5 |

WLG1400-2500 |

3.5 |

HYB-7.5-3V |

111 |

WBOG54/3-0.42 |

162 |

42 |

80GDL54-14×3 |

11 |

WLG1400-2500 |

3.5 |

HYB-11-3V |

112 |

WBOG54/3-0.56 |

162 |

56 |

80GDL54-14×4 |

15 |

WLG1400-2500 |

3.5 |

HYB-15-3V |

113 |

WBOG54/3-0.70 |

162 |

70 |

80GDL54-14×5 |

18.5 |

WLG1400-2500 |

3.5 |

HYB-18.5-3V |

114 |

WBOG54/3-0.84 |

162 |

84 |

80GDL54-14×6 |

18.5 |

WLG1400-2500 |

3.5 |

HYB-18.5-3V |

115 |

WBOG54/3-0.98 |

162 |

98 |

80GDL54-14×7 |

22 |

WLG1400-2500 |

3.5 |

HYB-22-3V |

116 |

WBOG54/3-1.12 |

162 |

112 |

80GDL54-14×8 |

30 |

WLG1400-2500 |

3.5 |

HYB-30-3V |

117 |

WBOG54/3-1.26 |

162 |

126 |

80GDL54-14×9 |

30 |

WLG1400-2500 |

3.5 |

HYB-30-3V |

118 |

WBOG54/3-1.40 |

162 |

140 |

80GDL54-14×10 |

37 |

WLG1400-2500 |

3.5 |

HYB-37-3V |

119 |

WBOG72/3-0.28 |

216 |

28 |

100GDL72-14×2 |

11 |

WLG1600-3300 |

6.0 |

HYB-11-3V |

120 |

WBOG72/3-0.42 |

216 |

42 |

100GDL72-14×3 |

15 |

WLG1600-3300 |

6.0 |

HYB-15-3V |

121 |

WBOG72/3-0.56 |

216 |

56 |

100GDL72-14×4 |

18.5 |

WLG1600-3300 |

6.0 |

HYB-18.5-3V |

122 |

WBOG72/3-0.70 |

216 |

70 |

100GDL72-14×5 |

22 |

WLG1600-3300 |

6.0 |

HYB-22-3V |

123 |

WBOG72/3-0.84 |

216 |

84 |

100GDL72-14×6 |

30 |

WLG1600-3300 |

6.0 |

HYB-30-3V |

124 |

WBOG72/3-0.98 |

216 |

98 |

100GDL72-14×7 |

30 |

WLG1600-3300 |

6.0 |

HYB-30-3V |

125 |

WBOG72/3-1.12 |

216 |

112 |

100GDL72-14×8 |

37 |

WLG1600-3300 |

6.0 |

HYB-37-3V |

126 |

WBOG72/3-1.26 |

216 |

126 |

100GDL72-14×9 |

37 |

WLG1600-3300 |

6.0 |

HYB-37-3V |

127 |

WBOG72/3-1.40 |

216 |

140 |

100GDL72-14×10

|

45 |

WLG1600-3300 |

6.0 |

HYB-45-3V |

128 |

WBOG108/3-0.40

|

324 |

40 |

125GDL100-20×2

|

18.5 |

WLG1600-3300 |

6.0 |

HYB-18.5-3V |

129 |

WBOG108/3-0.60 |

324 |

60 |

125GDL100-20×3 |

30 |

WLG1600-3300 |

6.0 |

HYB-30-3V |

130 |

WBOG108/3-0.80 |

324 |

80 |

125GDL100-20×4 |

37 |

WLG1600-3300 |

6.0 |

HYB-37-3V |

131 |

WBOG108/3-1.00 |

324 |

100 |

125GDL100-20×5 |

45 |

WLG1600-3300 |

6.0 |

HYB-45-3V |

132 |

WBOG108/3-1.20 |

324 |

120 |

125GDL100-20×6 |

55 |

WLG1600-3300 |

6.0 |

HYB-55-3V |

133 |

WBOG108/3-1.40

|

324 |

140 |

125GDL100-20×7 |

75 |

WLG1600-3300 |

6.0 |

HYB-75-3V |

134 |

WBOG108/3-1.60 |

324 |

160 |

125GDL100-20×8 |

75 |

WLG1600-3300 |

6.0 |

HYB-75-3V |

135 |

WBOG108/3-1.80 |

324 |

180 |

125GDL100-20×9 |

90 |

WLG1600-3300 |

6.0 |

HYB-90-3V |

136 |

WBOG108/3-2.00 |

324 |

200 |

125GDL100-20×10 |

90 |

WLG1600-3300 |

6.0 |

HYB-90-3V |

137 |

WBOG162/3-0.40 |

486 |

40 |

150GDL160-20×2

|

30 |

WLG2000-4000 |

HYB-30-3V |

|

138 |

WBOG162/3-0.60 |

486 |

60 |

150GDL160-20×3 |

37 |

WLG2000-4000 |

HYB-37-3V |

|

139 |

WBOG162/3-0.80 |

486 |

80 |

150GDL160-20×4 |

55 |

WLG2000-4000 |

HYB-55-3V |

|

140 |

WBOG162/3-1.00 |

486 |

100 |

150GDL160-20×5 |

75 |

WLG2000-4000 |

HYB-75-3V |

|

141 |

WBOG162/3-1.20 |

486 |

120 |

150GDL160-20×6 |

75 |

WLG2000-4000 |

HYB-75-3V |

|

142 |

WBOG162/3-1.40 |

486 |

140 |

150GDL160-20×7 |

90 |

WLG2000-4000 |

HYB-90-3V |

|

143 |

WBOG162/3-1.60 |

486 |

160 |

150GDL160-20×8 |

110 |

WLG2000-4000 |

HYB-110-3V |

|

144 |

WBOG162/3-1.80 |

486 |

180 |

150GDL160-20×9 |

110 |

WLG2000-4000 |

HYB-110-3V |

|

145 |

WBOG162/3-2.00 |

486 |

200 |

150GDL160-20×10 |

132 |

WLG2000-4000 |

HYB-132-3V |

|

Serial Number |

Equipment model

|

internet traffic |

lift |

Pump model

|

power |

Stable flow tank |

Equipped with control cabinet

|

|

m3/h |

m |

kW |

Specification (Dg-L) |

volume |

||||

146 |

WBOL6.3/2-0.20 |

12.6 |

20 |

LS40-20/2/1.5 |

1.5 |

WLG600-1000 |

0.25 |

HYB-1.5-2 |

147 |

WBOL6.3/2-0.28 |

11.8 |

28 |

LS40-28/2/2.2 |

2.2 |

WLG600-1000 |

0.25 |

HYB-2.2-2 |

148 |

WBOL6.3/2-0.38 |

11 |

38 |

LS40-38/2/3 |

3 |

WLG600-1000 |

0.25 |

HYB-3-2 |

149 |

WBOL6.3/2-0.50 |

12.6 |

50 |

LS40-50/2/4 |

5.5 |

WLG600-1000 |

0.25 |

HYB-5.5-2 |

150 |

WBOL6.3/2-0.60 |

11 |

60 |

LS40-60/2/4 |

7.5 |

WLG600-1000 |

0.25 |

HYB-7.5-2 |

151 |

WBOL6.3/2-0.70 |

11.8 |

70 |

LS40-70/2/5.5 |

7.5 |

WLG600-1000 |

0.25 |

HYB-7.5-2 |

152 |

WBOL6.3/2-0.80 |

12.6 |

80 |

LS40-80/2/7.5 |

11 |

WLG600-1000 |

0.25 |

HYB-11-2 |

153 |

WBOL12.5/2-0.125 |

25 |

12.5 |

LS50-12.5/2/1.1 |

1.1 |

WLG800-1300 |

0.58 |

HYB-1.1-2 |

154 |

WBOL12.5/2-0.20 |

25 |

20 |

LS50-20/2/1.5 |

1.5 |

WLG800-1300 |

0.58 |

HYB-1.5-2 |

155 |

WBOL11/2-0.28 |

22 |

28 |

LS50-28/2/2.2 |

2.2 |

WLG800-1300 |

0.58 |

HYB-2.2-2 |

156 |

WBOL10/2-0.35 |

20 |

35 |

LS50-35/2/3 |

3 |

WLG800-1300 |

0.58 |

HYB-3-2 |

157 |

WBOL12.5/2-0.5 |

25 |

50 |

LS50-50/2/5.5 |

5.5 |

WLG800-1300 |

0.58 |

HYB-5.5-2 |

158 |

WBOL10/2-0.6 |

20 |

60 |

LS50-60/2/7.5 |

7.5 |

WLG800-1300 |

0.58 |

HYB-7.5-2 |

159 |

WBOL11/2-0.7 |

22 |

70 |

LS50-70/2/7.5 |

7.5 |

WLG800-1300 |

0.58 |

HYB-7.5-2 |

160 |

WBOL12.5/2-0.8 |

25 |

80 |

LS50-80/2/11 |

11 |

WLG800-1300 |

0.58 |

HYB-11-2 |

161 |

WBOL25/2-0.125

|

50 |

12.5 |

LS65-12.5/2/1.5 |

1.5 |

WLG1000-1600 |

1.1 |

HYB-1.5-2 |

162 |

WBOL23.4/2-0.28 |

46.8 |

28 |

LS65-28/2/4 |

4 |

WLG1000-1600 |

1.1 |

HYB-4-2 |

163 |

WBOL20/2-0.38 |

40 |

38 |

LS65-38/2/5.5 |

5.5 |

WLG1000-1600 |

1.1 |

HYB-5.5-2 |

164 |

WBOL25/2-0.50 |

50 |

50 |

LS65-50/2/7.5 |

7.5 |

WLG1000-1600 |

1.1 |

HYB-7.5-2 |

165 |

WBOL20/2-0.60 |

40 |

60 |

LS65-60/2/11 |

11 |

WLG1000-1600 |

1.1 |

HYB-11-2 |

166 |

WBOL23.4/2-0.70 |

46.8 |

70 |

LS65-70/2/11 |

11 |

WLG1000-1600 |

1.1 |

HYB-11-2 |

167 |

WBOL25/2-0.80 |

50 |

80 |

LS65-80/2/15 |

15 |

WLG1000-1600 |

1.1 |

HYB-15-2 |

168 |

WBOL50/2-0.125 |

100 |

12.5 |

LS80-12.5/2/3 |

3 |

WLG1200-2000 |

2.0 |

HYB-3-2 |

169 |

WBOL46.8/2-0.28 |

93.6 |

28 |

LS80-28/2/7.5 |

7.5 |

WLG1200-2000 |

2.0 |

HYB-7.5-2 |

170 |

WBOL42/2-0.38 |

84 |

38 |

LS80-38/2/7.5 |

7.5 |

WLG1200-2000 |

2.0 |

HYB-7.5-2 |

171 |

WBOL50/2-0.50 |

100 |

50 |

LS80-50/2/15 |

15 |

WLG1200-2000 |

2.0 |

HYB-15-2 |

172 |

WBOL43/2-0.60 |

86 |

60 |

LS80-60/2/15 |

15 |

WLG1200-2000 |

2.0 |

HYB-15-2 |

173 |

WBOL46.8/2-0.70 |

93.6 |

70 |

LS80-70/2/15 |

18.5 |

WLG1200-2000 |

2.0 |

HYB-18.5-2 |

174 |

WBOL50/2-0.80 |

100 |

80 |

LS80-80/2/22 |

22 |

WLG1200-2000 |

2.0 |

HYB-22-2 |

Serial Number |

Equipment model

|

internet traffic |

lift |

Pump model

|

power |

Stable flow tank |

Equipped with control cabinet

|

|

m3/h |

m |

kW |

Specification (Dg-L) |

volume |

||||

175 |

WBOL100/2-0.125 |

200 |

12.5 |

LS100-12.5/2/5.5

|

5.5 |

WLG1400-2500 |

3.5 |

HYB-5.5-2 |

176 |

WBOL93/2-0.28 |

186 |

28 |

LS100-28/2/11 |

11 |

WLG1400-2500 |

3.5 |

HYB-11-2 |

177 |

WBOL86/2-0.38 |

172 |

38 |

LS100-38/2/15 |

15 |

WLG1400-2500 |

3.5 |

HYB-15-2 |

178 |

WBOL100/2-0.50 |

200 |

50 |

LS100-50/2/22 |

22 |

WLG1400-2500 |

3.5 |

HYB-22-2 |

179 |

WBOL86/2-0.60 |

172 |

60 |

LS100-60/2/30 |

30 |

WLG1400-2500 |

3.5 |

HYB-30-2 |

180 |

WBOL93/2-0.70 |

176 |

70 |

LS100-70/2/30 |

30 |

WLG1400-2500 |

3.5 |

HYB-30-2 |

181 |

WBOL100/2-0.80 |

200 |

80 |

LS100-80/2/37 |

37 |

WLG1400-2500 |

3.5 |

HYB-37-2 |

182 |

WBOL160/2-0.125 |

320 |

12.5 |

LS125-12.5/2/11 |

11 |

WLG1600-3300 |

6.0 |

HYB-11-2 |

183 |

WBOL160/2-0.20 |

320 |

20 |

LS125-20/2/15 |

15 |

WLG1600-3300 |

6.0 |

HYB-15-2 |

184 |

WBOL187/2-0.28 |

374 |

28 |

LS125-28/2/22 |

22 |

WLG1600-3300 |

6.0 |

HYB-22-2 |

185 |

WBOL200/2-0.32 |

400 |

32 |

LS125-32/2/30 |

30 |

WLG1600-3300 |

6.0 |

HYB-30-2 |

186 |

WBOL187/2-0.44 |

374 |

44 |

LS125-44/2/30 |

30 |

WLG1600-3300 |

6.0 |

HYB-37-2 |

187 |

WBOL200/2-0.50 |

400 |

50 |

LS125-50/2/45 |

45 |

WLG1600-3300 |

6.0 |

HYB-45-2 |

188 |

WBOL172/2-0.60 |

344 |

60 |

LS125-60/2/45 |

45 |

WLG1600-3300 |

6.0 |

HYB-45-2 |

189 |

WBOL187/2-0.70 |

374 |

70 |

LS125-70/2/55 |

55 |

WLG1600-3300 |

6.0 |

HYB-55-2 |

190 |

WBOL200/2-0.80 |

400 |

80 |

LS125-80/2/75 |

75 |

WLG1600-3300 |

6.0 |

HYB-75-2 |

191 |

WBOL200/2-0.125 |

400 |

12.5 |

LS150-12.5/4/15 |

15 |

WLG2000-4000 |

HYB-15-2 |

|

192 |

WBOL200/2-0.20 |

400 |

20 |

LS150-20/4/18.5 |

18.5 |

WLG2000-4000 |

HYB-18.5-2 |

|

193 |

WBOL150/2-0.28 |

300 |

28 |

LS150-28/4/18.5 |

18.5 |

WLG2000-4000 |

HYB-18.5-2 |

|

194 |

WBOL200/2-0.32 |

400 |

32 |

LS150-32/4/30 |

30 |

WLG2000-4000 |

HYB-30-2 |

|

195 |

WBOL150/2-0.44 |

300 |

44 |

LS150-44/4/30 |

30 |

WLG2000-4000 |

HYB-30-2 |

|

196 |

WBOL200/2-0.50 |

400 |

50 |

LS150-50/4/45 |

45 |

WLG2000-4000 |

HYB-45-2 |

|

197 |

WBOL172/2-0.60 |

332 |

60 |

LS150-60/2/45 |

45 |

WLG2000-4000 |

HYB-45-2 |

|

198 |

WBOL182/2-0.70 |

364 |

70 |

LS150-70/2/55 |

55 |

WLG2000-4000 |

HYB-55-2 |

|

199 |

WBOL200/2-0.80 |

400 |

80 |

LS150-80/2/75 |

75 |

WLG2000-4000 |

HYB-75-2 |

|

Serial Number |

Equipment model

|

internet traffic |

lift |

Pump model

|

power |

Stable flow tank |

Equipped with control cabinet

|

|

m3/h |

m |

kW |

Specification (Dg-L) |

volume |

||||

Previous: QHYB-CDL Variable Frequency Constant Pressure Water Supply Equipment

Next article: QHYX-DL Fire Boosting Complete Equipment