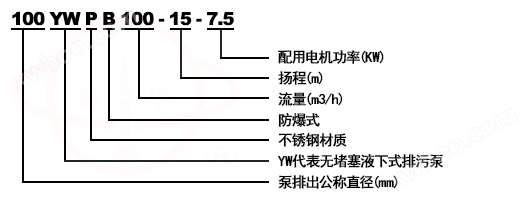

Model Meaning

Product Introduction

The YW unobstructed sewage submersible pump is developed through absorption and conversion, and all performance indicators meet the national standard for similar products. Due to the use of unique single (double) channel impellers, it has strong drainage capacity and can effectively pass through 5 times the diameter of the pump and solid particles with a diameter of 50% of the pump diameter. The dynamic seal adopts two sets of special hard alloy mechanical seal devices made of cast iron and stainless steel.

Product Features

1. Adopting a double blade impeller structure greatly improves the ability of pollutants to pass through

2. The mechanical seal adopts a new type of friction pair and operates in the oil chamber for a long time;

3. The overall structure is compact, small in size, low in noise, easy to maintain, and convenient for users to replace;

4. The automatic control cabinet can automatically control the pump's over movement and stop according to the required liquefaction changes, without the need for dedicated personnel to supervise, making it extremely convenient to use;

5. Installation methods can be provided according to user needs, which greatly facilitates installation and maintenance. People do not need to enter the sewage pit for this purpose;

6. Can be used within the design scope while ensuring that the motor does not overload;

7. If the pump is equipped with an outdoor motor, there is no need to build a pump room, and it can be directly installed and used outdoors to save costs;

Product Usage

YW unobstructed sewage submersible pump is suitable for the discharge of severely polluted wastewater in factories and commercial areas, sewage discharge stations in main residential areas, water distribution systems in urban sewage treatment plants, drainage stations in civil air defense systems, water supply equipment in waterworks, sewage discharge in hospitals and hotels, municipal engineering construction sites, mining supporting machinery, rural biogas digesters, farmland irrigation and other industries. It can also be used for conveying granular sewage and pollutants, as well as for clean water and weakly corrosive media.

working conditions

A、 The operating environment temperature of the pump is ≤ 40 ℃, and the humidity is ≤ 95%; Altitude ≤ 1000 meters.

B、 The medium temperature shall not exceed 60 ℃, and the medium density shall be 1-1.3kg/dm3.

C、 The range of use for cast iron material is from pH 5 to 9.

D、 Stainless steel material can be used with general corrosive media.

E、 The altitude of the usage environment should not exceed 1000 meters. If it exceeds the above conditions, it should be mentioned when placing an order to provide you with more reliable products.

Note: If the user has special requirements for temperature, medium, etc., please specify the detailed information of the conveying medium when ordering, so that our unit can provide more reliable products.

structural diagram

|

serial number |

name |

serial number |

name |

1

|

motor |

12

|

oil chamber |

|

2

|

coupling |

13

|

oil seal |

|

3

|

Connecting end caps |

14

|

pump cover |

|

4

|

bearing cover |

15

|

impeller nut |

|

5

|

Install flat disc |

16

|

impeller |

|

6

|

bearing housing |

17

|

Water outlet bend pipe |

|

7

|

bearing |

18

|

pump body |

|

8

|

Extended shaft |

19

|

Wear resistant body |

|

9

|

support tube |

20

|

base |

|

10

|

bearing |

21

|

Liquid outlet pipe |

|

11

|

mechanical seal |

performance parameters

model |

caliber |

traffic |

head |

speed |

power |

efficiency |

mm |

(m3/h) |

(M) |

(r/min) |

(kw) |

(%) |

|

25-7-8-0.55 |

25 |

7 |

8 |

2900 |

0.55 |

45 |

25-8-22-1.1 |

25 |

8 |

22 |

2900 |

1.1 |

45 |

32-8-12-0.75 |

32 |

8 |

12 |

2900 |

0.75 |

48 |

32-12-15-1.1 |

32 |

12 |

15 |

2900 |

1.1 |

45 |

40-15-15-1.5 |

40 |

15 |

15 |

2900 |

1.5 |

48 |

40-15-30-2.2 |

40 |

15 |

30 |

2900 |

2.2 |

54 |

50-20-7-0.75 |

50 |

20 |

7 |

2900 |

0.75 |

51 |

50-10-10-0.75 |

50 |

10 |

10 |

2900 |

0.75 |

52 |

50-20-15-1.5 |

50 |

20 |

15 |

290 |

1.5 |

53 |

50-15-25-2.2 |

50 |

15 |

25 |

2900 |

2.2 |

54 |

50-18-30-3 |

50 |

18 |

30 |

2900 |

3 |

55 |

50-40-15-4 |

50 |

40 |

15 |

2900 |

4 |

55 |

50-25-32-5.5 |

50 |

25 |

32 |

2900 |

5.5 |

55 |

50-20-40-7.5 |

50 |

50 |

20 |

2900 |

7.5 |

58 |

65-25-15-2.2 |

65 |

25 |

15 |

2900 |

2.2 |

50 |

65-37-13-3 |

65 |

37 |

13 |

2900 |

3 |

57 |

65-25-30-4 |

65 |

25 |

30 |

2900 |

4 |

61 |

65-30-40-7.5 |

65 |

30 |

40 |

2900 |

7.5 |

56 |

65-35-50-11 |

65 |

35 |

50 |

2900 |

11 |

45 |

65-35-60-15 |

65 |

35 |

60 |

2900 |

15 |

65 |

80-40-7-2.2 |

80 |

40 |

7 |

1450 |

2.2 |

59 |

80-43-13-3 |

80 |

43 |

13 |

2900 |

3 |

70 |

80-40-15-4 |

80 |

40 |

15 |

2900 |

4 |

61 |

80-60-13-5.5 |

80 |

60 |

13 |

2900 |

5.5 |

67 |

80-65-25-7.5 |

80 |

65 |

25 |

2900 |

7.5 |

63 |

model |

caliber |

traffic |

head |

speed |

power |

efficiency |

mm |

(m3/h) |

(M) |

(r/min) |

(kw) |

(%) |

|

100-80-10-4 |

100 |

100 |

10 |

1450 |

4 |

65 |

100-100-15-7.5 |

100 |

100 |

15 |

1450 |

7.5 |

68 |

100-80-20-7.5 |

100 |

80 |

20 |

1450 |

7.5 |

65 |

100-100-25-11 |

100 |

100 |

25 |

1450 |

11 |

70 |

100-100-30-15 |

100 |

100 |

30 |

1450 |

15 |

65 |

100-100-35-18.5 |

100 |

100 |

35 |

1450 |

18.5 |

68 |

125-130-15-11 |

125 |

130 |

15 |

1450 |

11 |

72 |

125-130-20-15 |

125 |

130 |

20 |

1450 |

15 |

75 |

150-145-9-7.5 |

150 |

145 |

9 |

1450 |

7.5 |

76 |

150-180-15-15 |

150 |

180 |

15 |

1450 |

15 |

69 |

150-180-20-18.5 |

150 |

180 |

20 |

1450 |

18.5 |

72 |

150-180-25-22 |

150 |

180 |

25 |

1450 |

22 |

78 |

150-130-30-22 |

150 |

130 |

30 |

1450 |

22 |

78 |

150-180-30-30 |

150 |

180 |

30 |

1450 |

30 |

78 |

150-200-30-37 |

150 |

200 |

30 |

1450 |

37 |

73 |

200-300-7-11 |

200 |

300 |

7 |

980 |

11 |

66 |

200-250-11-15 |

200 |

250 |

11 |

1450 |

15 |

64 |

200-250-15-18.5 |

200 |

250 |

15 |

1450 |

18.5 |

73 |

200-400-10-22 |

200 |

400 |

10 |

1450 |

22 |

75 |

200-400-13-30 |

200 |

400 |

13 |

14501 |

30 |

76 |

200-300-15-22 |

200 |

300 |

15 |

1450 |

22 |

76 |

200-250-22-30 |

200 |

250 |

22 |

1450 |

30 |

71 |

200-350-25-37 |

200 |

350 |

25 |

1450 |

37 |

71 |

200-400-30-45 |

200 |

400 |

30 |

1450 |

45 |

74 |

model |

caliber |

traffic |

head |

speed |

power |

efficiency |

mm |

(m3/h) |

(M) |

(r/min) |

(kw) |

(%) |

|

250-600-9-30 |

250 |

600 |

9 |

980 |

30 |

78 |

250-600-12-37 |

250 |

600 |

12 |

1450 |

37 |

76 |

250-600-15-45 |

250 |

600 |

15 |

1450 |

45 |

73 |

250-600-20-55 |

250 |

600 |

20 |

1450 |

55 |

73 |

250-600-25-75 |

250 |

600 |

25 |

1450 |

75 |

71 |

300-800-12-45 |

300 |

800 |

12 |

980 |

45 |

74 |

300-480-15-45 |

300 |

480 |

15 |

1450 |

45 |

66 |

300-800-15-55 |

300 |

800 |

15 |

1450 |

55 |

73 |

300-600-20-55 |

300 |

600 |

20 |

1450 |

55 |

73 |

300-800-20-75 |

300 |

800 |

20 |

1450 |

75 |

75 |

300-950-20-90 |

300 |

950 |

20 |

1450 |

90 |

76 |

300-1000-25-110 |

300 |

1000 |

25 |

1450 |

110 |

76 |

300-1100-10-55 |

300 |

1100 |

10 |

1450 |

55 |

73 |

350-1500-15-90 |

350 |

1500 |

15 |

740 |

90 |

87 |

350-1200-18-90 |

350 |

1200 |

18 |

980 |

90 |

85 |

350-1100-28-132 |

350 |

1100 |

28 |

980 |

132 |

84 |

350-1000-36-160 |

350 |

1000 |

36 |

980 |

160 |

84 |

400-1760-7.5-55 |

400 |

1760 |

7.5 |

980 |

55 |

83 |

400-1500-10-75 |

400 |

1500 |

10 |

980 |

75 |

86 |

400-2000-13-110 |

400 |

2000 |

13 |

980 |

110 |

84 |

400-2000-15-132 |

400 |

2000 |

15 |

980 |

132 |

83 |

400-1700-22-160 |

400 |

1700 |

22 |

980 |

160 |

83 |

400-1500-26-160 |

400 |

1500 |

26 |

980 |

160 |

84 |

model |

caliber |

traffic |

head |

speed |

power |

efficiency |

mm |

(m3/h) |

(M) |

(r/min) |

(kw) |

(%) |

|

400-1800-32-250 |

400 |

1800 |

32 |

980 |

250 |

82 |

500-2500-10-110 |

500 |

2500 |

10 |

740 |

110 |

85 |

500-2600-15-160 |

500 |

2600 |

15 |

740 |

160 |

84 |

500-2400-22-220 |

500 |

2400 |

22 |

740 |

220 |

85 |

500-2650-24-250 |

500 |

2650 |

24 |

740 |

250 |

85 |

Fault analysis and troubleshooting methods

Fault phenomenon |

Root cause analysis |

exclusion method |

Insufficient flow or no water output |

1. Impeller rotation error 2. Is the valve open and intact 3. The pipeline impeller is blocked 4. Head too high 5. The density of the pumping medium is relatively high 6. Damaged sealing ring |

1. Adjust the rotation direction of the impeller 2. Check, repair, and eliminate 3. Clean up debris 4. Change the pump or reduce the head 5. Dilute with water to reduce concentration 6. Replace |

Unstable operation |

1. Unbalanced impeller 2. Bearing damage |

1、 送制造厂调换或校正 2. Replace |

The pump cannot start |

1. Lack of phase 2. Impeller stuck 3、 定子绕组烧坏 |

1. Check electrical appliances and circuits, and repair them 2. Remove debris 3. Repair and replace the winding |

excessive current |

1. Low working voltage 2. Pipeline and impeller are obstructed 3. The height or viscosity of the liquid being pumped is high 4. Using a low head |

1. Adjust the working voltage 2. Clean up blockages in pipelines and impellers 3. Change density or viscosity 4. Reduce flow and increase head |

Insufficient pressure |

1. Mechanical seal damage or leakage 2. Cable damage |

1. Replace 2. Replace |